Welcome back:

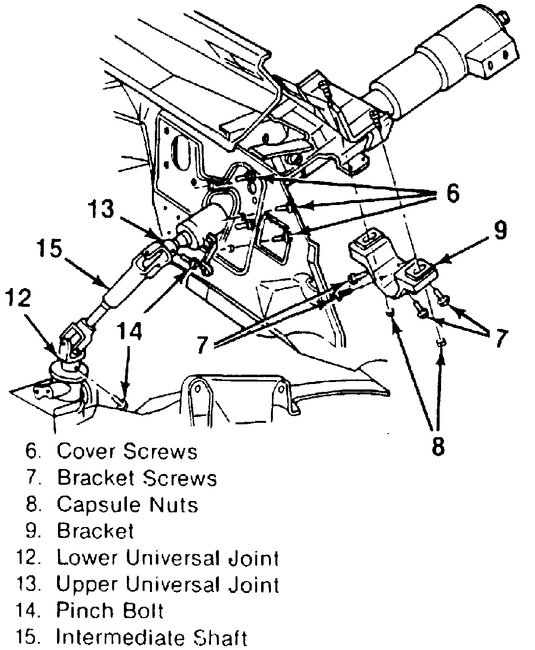

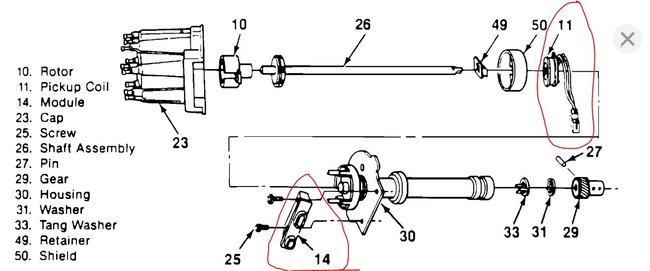

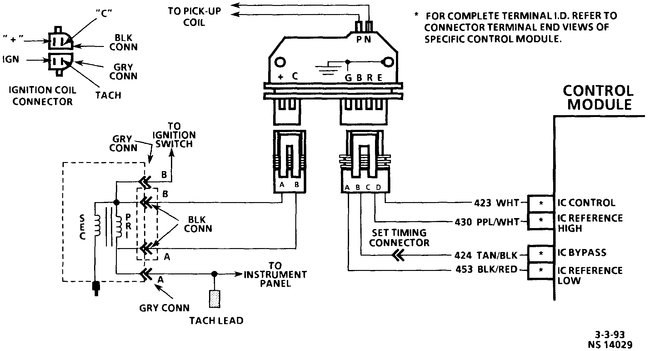

I didn't realize that was the issue. The first suspect on this vehicle is either the pick up coil or ignition control module in the distributor. See picture 1 You indicated replacement of parts in distributor. Were both replaced? Have you checked the coil?

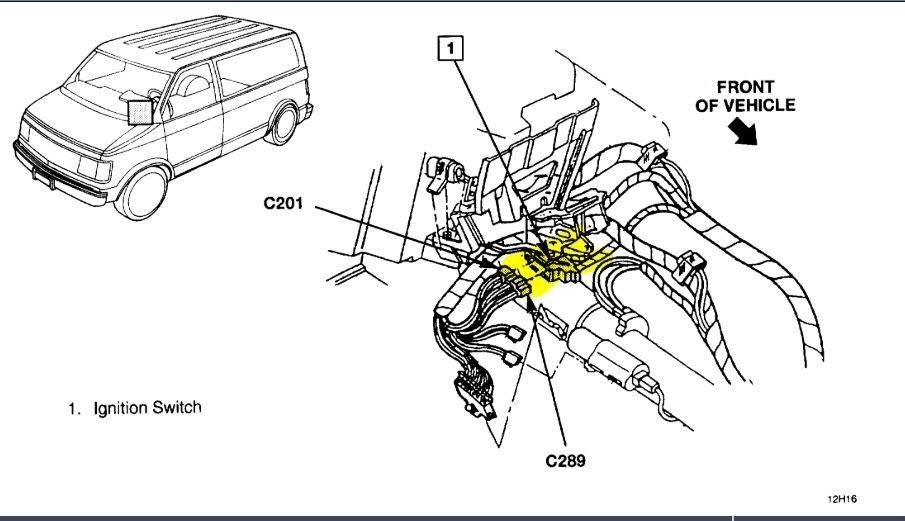

Chances are it has nothing to do with the ignition switch.

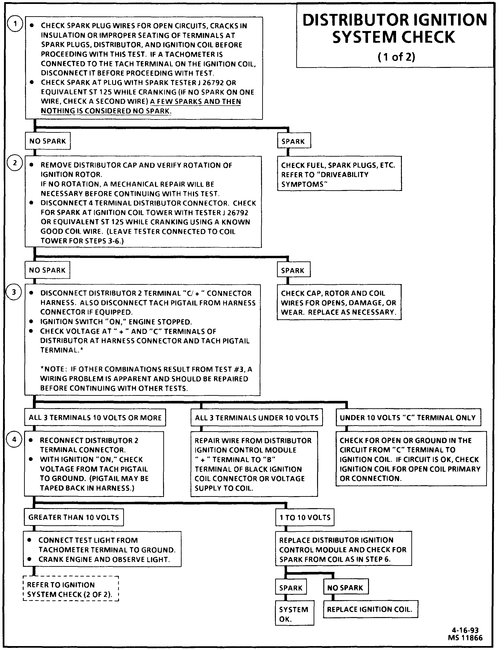

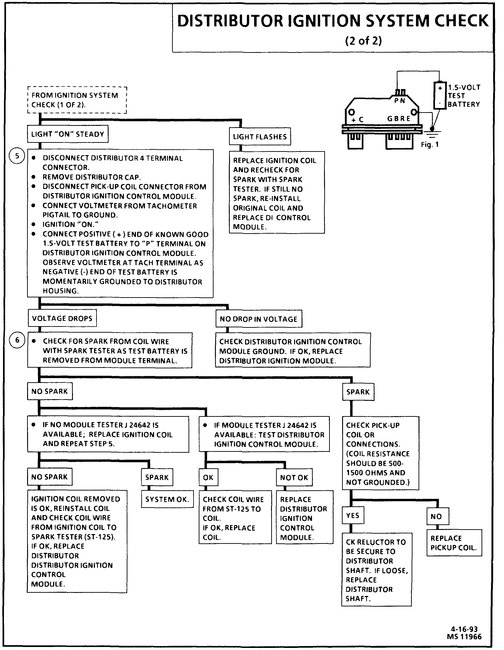

If you look at pics 2, 3, and 4, they indicate how to check.

Here are the additions to the pictures.

______________________________________________

CHART TEST DESCRIPTION:

Number(s) below refer to circled number(s) on the diagnostic chart.

1. Two wires are checked, to ensure that an open is not present in a spark plug wire. This step also checks for mechanical problems.

2. A spark indicates the problem must be the distributor cap, rotor, or coil output wire.

3. Normally, there should be battery voltage at the "C" and "+" terminals on the coil connector. Low voltage would indicate an open or a high resistance circuit from the distributor to the coil or ignition switch. If "C" terminal voltage was low, but "+" terminal voltage is 10 volts or more, circuit from "C" terminal to ignition coil or ignition coil primary winding is open.

4. Checks for a shorted module or grounded circuit from the ignition coil to the module. The distributor module should be turned "OFF, " so normal voltage should be about 12 volts.

If the module is turned "ON, " the voltage would be low, but above 1 volt. This could cause the ignition coil to fail from excessive heat.

With an open ignition coil primary winding, a small amount of voltage will leak through the module from the "Batt" to the "Tach" terminal.

5. Applying a voltage (1.35 to 1.50 volts) to module terminal "P" should turn the module "ON" and the "Tach" terminal voltage should drop to about 7-9 volts. This test will determine whether the module or coil is faulty or if the pick-up coil is not generating the proper signal to turn the module "ON." This test can be performed by using a DC test battery with a rating of 1.5 volts. (Such as AA, C, or D cell.) The battery must be a known good battery with a voltage of over 1.35 volts.

6. This should turn "OFF" the module and cause a spark. If no spark occurs, the fault is most likely in the ignition coil because most module problems would have been found before this point in the procedure. A distributor ignition control module tester (J 24642) could determine which is at fault.

______________________________________________

Here are the directions for replacement if you find the module is bad.

REMOVE OR DISCONNECT

NOTE It is not necessary to remove ignition distributor assembly from engine.

- Distributor cap and rotor.

- Connectors from module.

- Two module attaching screws.

- Lift module from housing and remove.

INSTALL OR CONNECT

NOTE: Do not wipe silicone grease from metal face of module or distributor base (where the module seats), when reinstalling the same module. If new module is to be installed clean distributor module base and spread new silicone grease on base and metal face of ignition module. The purpose of the silicone grease is to cool module.

- Module onto housing.

- Module attaching screws. Tighten to 2 Nm (18 lb. In.)

- Connectors to module.

- Rotor and cap.

____________________________

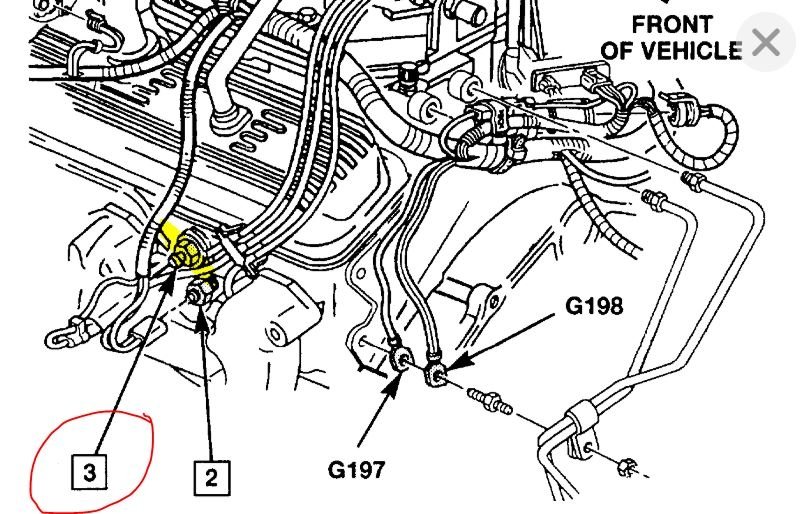

As far as the knock sensor, the last pic attached shows its location. I don't think that is the issue.

___________________________

Let me know if any of this helps.

Take care,

Joe

Images (Click to make bigger)

Tuesday, October 29th, 2019 AT 9:37 PM