Hi and thanks for using 2CarPros.com.

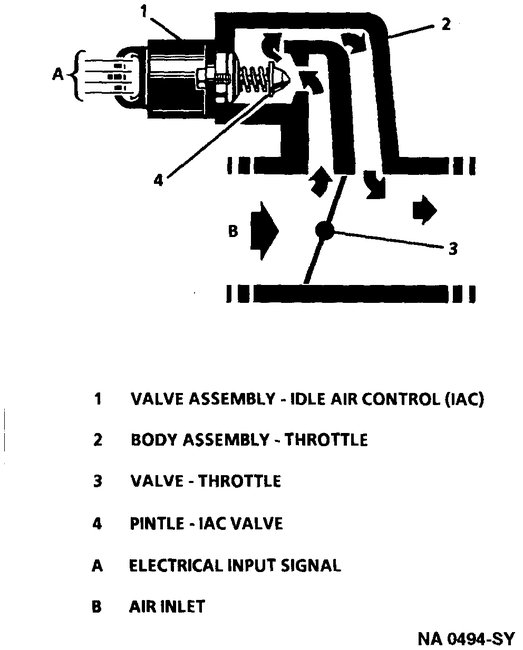

This could be the result of a few things. However, I first recommend checking the idle air control (IAC) valve. This component is responsible for maintaining engine idle speed.

Here is a link that shows in general how one is checked and replaced:

https://www.2carpros.com/articles/how-to-replace-an-idle-speed-control-motor-iac

Here is a link that discusses high idle issues, how to diagnose them, and how to repair:

https://www.2carpros.com/articles/engine-idles-too-high

Please keep in mind, there are other things which can cause this type of issue. A bad crank sensor can prevent starting when hot, an engine vacuum leak can play havoc on the idle speed, the engine coolant temperature sensor (ect) can also cause starting and idle issues. However, the first plan of attach should be the IAC.

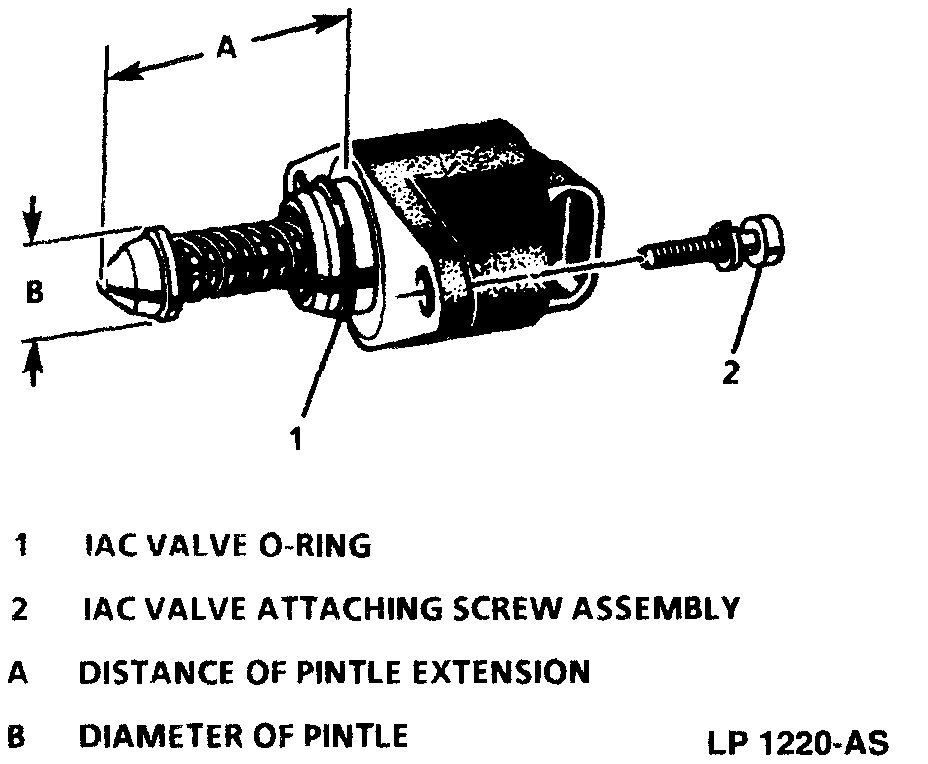

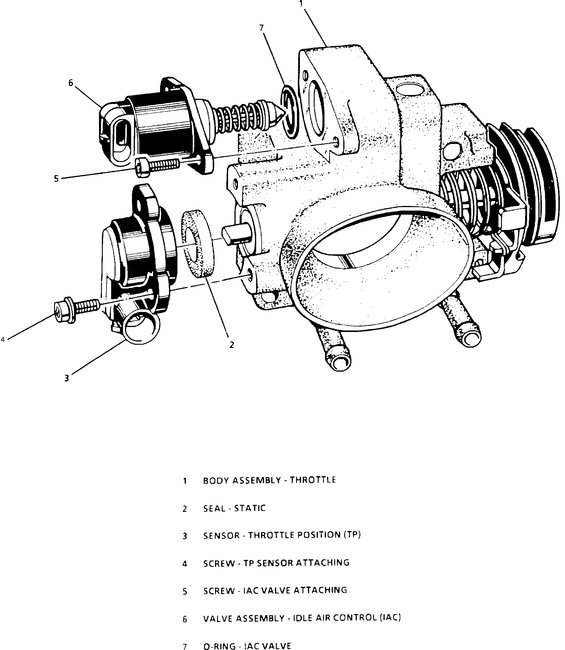

Picture 1 is of the component. Picture 2 is how it functions. Picture 3 shows its location on the throttle body.

Here are the directions specific to your vehicle for replacement if you find it is bad. Also, when you remove it to check its function, make sure there isn't a carbon build up on the valve as well as in the throttle body where it mounts.

___________________________________________

REMOVE OR DISCONNECT

1. Electrical connector.

2. Idle Air Control (IAC) valve attaching screws.

3. IAC valve assembly.

CAUTION: If IAC valve has been in service: Do not push or pull on the IAC valve pintle. The force required to move the pintle may damage the threads on the worm drive. Also, do not soak IAC valve in any liquid cleaner or solvent, as damage may result.

CLEAN AND INSPECT

- Clean IAC valve O-ring sealing surface, pintle valve seat, and air passage.

- Use carburetor cleaner and a parts cleaning brush to remove carbon deposits. Do not use a cleaner containing methyl ethyl ketone, an extremely strong solvent, and not necessary for this type of deposit.

- Shiny spots on the pintle or seat are normal and do not indicate misalignment or a bent pintle shaft.

- If air passage has heavy deposits, remove upper manifold assembly for complete cleaning.

- Inspect IAC valve O-ring for cuts, cracks, or distortion. Replace if damaged.

CAUTION: If installing a NEW IAC valve, be sure to replace with an identical part. IAC valve pintle shape and diameter are designed for the specific application.

Measure (only if Installing a New IAC Valve)

Distance between tip of IAC valve pintle and mounting flange (see image).

- If greater than 28 mm, use finger pressure to slowly retract the pintle. The force required to retract the pintle of a new valve will not cause damage to the valve.

INSTALL OR CONNECT

1. Lubricate IAC valve O-ring with clean engine oil.

2. IAC valve assembly.

3. Attaching screws coated with appropriate thread-locking material.

Tighten

IAC valve attaching screws to 3.4 Nm (30 lb. in.).

4. Electrical connector.

5. Reset IAC valve pintle position:

A. Disconnect negative battery cable for at least ten seconds to clear PCM memory.

B. Reconnect negative battery cable.

C. Start engine and check for proper idle operation.

___________________________

As I mentioned, check this first. Also, if the check engine light remains on with the engine, have the computer scanned to determine what diagnostic trouble codes are stored. Most parts stores will scan it for free.

I hope this helps. Let me know if you have other questions.

Take care,

Joe

Images (Click to make bigger)

SPONSORED LINKS

Monday, October 8th, 2018 AT 4:40 PM