Welcome to 2CarPros.

A high idle can be the result of a few things. First, take a look through this link. It discusses the most common causes of as high idle and how to fix it.

https://www.2carpros.com/articles/engine-idles-too-high

Next, the other most common cause of a high idle is an engine vacuum leak. Rubber vacuum hoses dry out and leak or even break. The result is unmetered air gets into the engine causing either a high idle or very low one.

Here is a link that shows how to check for a vacuum leak:

https://www.2carpros.com/articles/how-to-use-an-engine-vacuum-gauge

As far as cleaning the throttle body, if there is dirt built up on the throttle plate, it can cause this. Here is a link that shows in general how to clean a throttle body:

https://www.2carpros.com/articles/throttle-actuator-service

Also, the vehicle has what is called an idle speed throttle actuator. There is a relearn process if the idle speed is wrong. However, it is somewhat involved and requires a specific type of scanner to perform. I will provide the directions just in case it is something you can do. Also, at the end of the relearn procedure, it identifies specific things to check if the relearn didn't work. You will find several of them are things I already mentioned. The attached pictures correlate with these directions.

_______________________________

IDLE AIR VOLUME LEARNING

Idle Air Volume Learning

DESCRIPTION

Idle Air Volume Learning is an operation to learn the idle air volume that keeps each engine within the specific range. It must be performed under any of the following conditions:

- Each time electric throttle control actuator or ECM is replaced.

- Idle speed or ignition timing is out of specification.

PREPARATION

Before performing Idle Air Volume Learning, make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are missed for even a moment.

- Battery voltage: More than 12.9 V (At idle)

- Engine coolant temperature: 70 - 95 degrees C (158 - 203 degrees F)

- PNP switch: ON

- Electric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is started the headlamp will not be illuminated.

- Steering wheel: Neutral (Straight-ahead position)

- Vehicle speed: Stopped

- Transmission: Warmed-up

- A/T models

- With CONSULT-II: Drive vehicle until "FLUID TEMP SE" in "DATA MONITOR" mode of "A/T" system indicates less than 0.9 V.

- Without CONSULT-II: Drive vehicle for 10 minutes.

- M/T models

- Drive vehicle for 10 minutes.

OPERATION PROCEDURE

With CONSULT-II

1. Perform EC-79, "Accelerator Pedal Released Position Learning". See: Accelerator Pedal Position Sensor > Programming and Relearning > Accelerator Pedal Released Position Learning

2. Perform EC-80, "Throttle Valve Closed Position Learning". See: Computers and Control Systems > Programming and Relearning > Throttle Valve Closed Position Learning

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic PREPARATION (previously mentioned) are in good order.

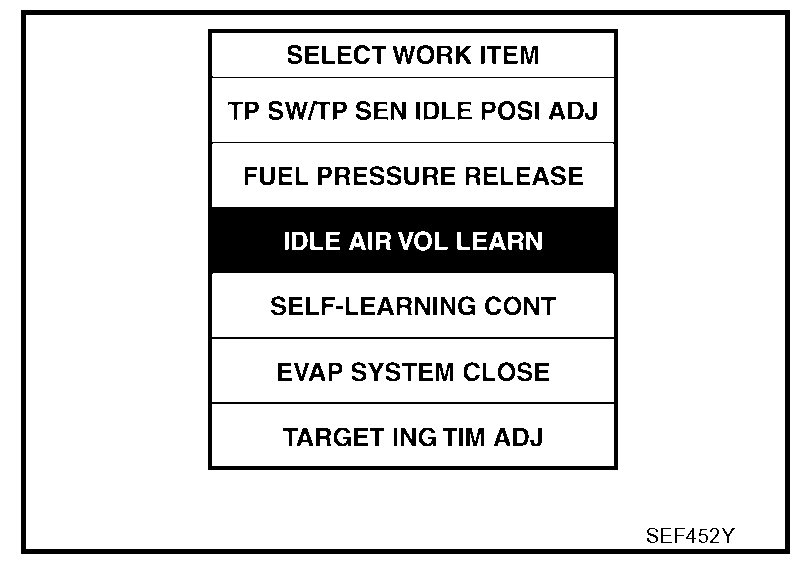

Picture 1

5. Select "IDLE AIR VOL LEARN" in "WORK SUPPORT" mode.

6. Touch "START" and wait 20 seconds.

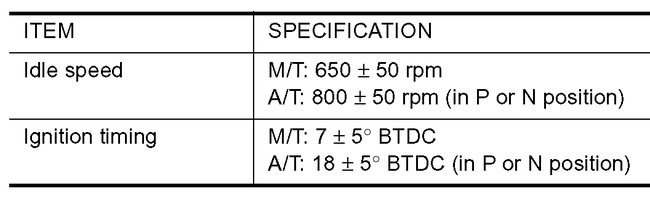

Picture 2

7. Make sure that "CMPLT" is displayed on CONSULT-II screen. If "CMPLT" is not displayed, Idle Air Volume Learning will not be carried out successfully. In this case, find the cause of the incident by referring to the Diagnostic Procedure.

8. Rev up the engine two or three times and make sure that idle speed and ignition timing are within the specifications. Refer to "IDLE SPEED".

Without CONSULT-II

NOTE:

- It is better to count the time accurately with a clock.

- It is impossible to switch the diagnostic mode when an accelerator pedal position sensor circuit has a malfunction.

1. Perform EC-79, "Accelerator Pedal Released Position Learning". See: Accelerator Pedal Position Sensor > Programming and Relearning > Accelerator Pedal Released Position Learning

2. Perform EC-80, "Throttle Valve Closed Position Learning". See: Computers and Control Systems > Programming and Relearning > Throttle Valve Closed Position Learning

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic PREPARATION (previously mentioned) are in good order.

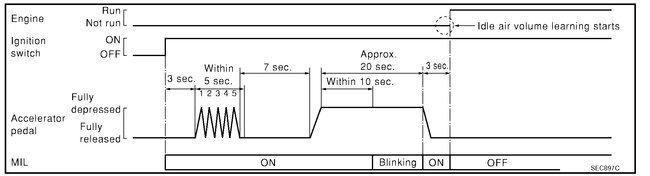

5. Turn ignition switch OFF and wait at least 10 seconds.

6. Confirm that accelerator pedal is fully released, turn ignition switch ON and wait 3 seconds.

7. Repeat the following procedure quickly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

8. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 20 seconds until the MIL stops blinking and turned ON.

9. Fully release the accelerator pedal within 3 seconds after the MIL turned ON.

10. Start engine and let it idle.

Picture 3

11. Wait 20 seconds.

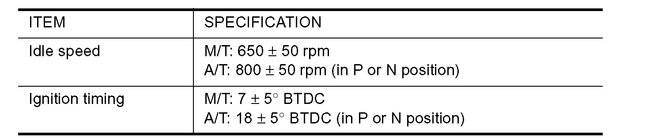

Picture 4

12. Rev up the engine two or three times and make sure that idle speed and ignition timing are within the specifications.

13. If idle speed and ignition timing are not within the specification, Idle Air Volume Learning will not be carried out successfully. In this case, find the cause of the incident by referring to the Diagnostic Procedure.

DIAGNOSTIC PROCEDURE

If idle air volume learning cannot be performed successfully, proceed as follows:

1. Check that throttle valve is fully closed.

2. Check PCV valve operation.

3. Check that downstream of throttle valve is free from air leakage.

4. When the above three items check out OK, engine component parts and their installation condition are questionable. Check and eliminate the cause of the incident. It is useful to perform EC-134, "TROUBLE DIAGNOSIS - SPECIFICATION VALUE". See: Computers and Control Systems > Monitors, Trips, Drive Cycles and Readiness Codes > Specification (SP) Value

5. If any of the following conditions occur after the engine has started, eliminate the cause of the incident and perform Idle air volume learning all over again:

- Engine stalls.

- Erroneous idle.

_________________________________

Let me know if this helps or if you have other questions.

Take care,

Joe

Images (Click to make bigger)

Sunday, March 24th, 2019 AT 6:18 PM