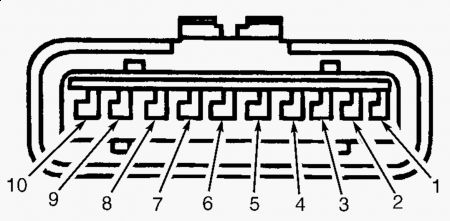

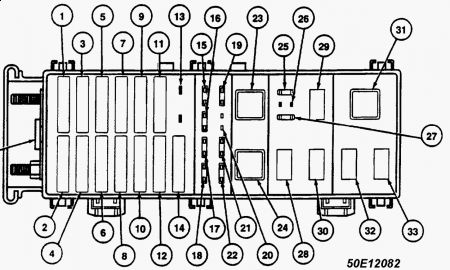

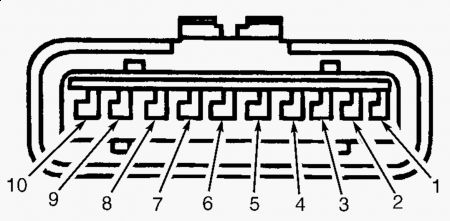

TESTING SYSTEM INOPERATIVE 1. Check Power To Servo - Unplug harness connector from servo. Turn ignition on. Using DVOM, measure voltage between pins No. 7 and 10 of servo connector. See Fig. 1 . If battery voltage exists, go to step 4). If battery voltage does not exist, go to next step. 2. Check Power To Servo - Turn ignition on. Check for battery voltage between servo connector pin No. 7 and chassis ground. If battery voltage exists, go to next step. If battery voltage does not exist, check fuses and replace as necessary. If fuses are okay, repair open power circuit. If fuse repeatedly blows check circuit for short to ground and repair as necessary. 3. Check Module Ground - Measure resistance between servo connector pin No. 10 and chassis ground. If resistance is less than 5 ohms, repeat step 1). If resistance is greater than 5 ohms, repair ground circuit. 4. Check Deactivator Switch Circuit - Turn ignition on. With brake released, measure voltage between pin No. 9 at servo connector and ground. If battery voltage exists, go to step 7). If battery voltage does not exist, go to next step. 5. Check Power To Deactivator Switch - Disconnect deactivator switch harness connector. See DEACTIVATOR SWITCH LOCATION table. Check for battery voltage at deactivator switch Light Green/Red wire. If battery voltage exists, go to next step. If battery voltage does not exist, check for blown fuse or open circuit. Repair as necessary.

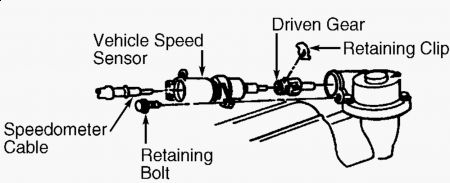

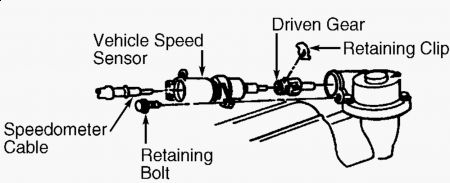

6. Check Deactivator Switch-To-Servo Circuit - Measure resistance between servo connector pin No. 9 and matching wire color at deactivator switch harness connector. If resistance is less than 5 ohms, replace deactivator switch. If resistance is greater than 5 ohms, repair open circuit between deactivator switch and servo connectors. 7. Check Stoplight Switch - With brake pedal released, measure voltage on pin No. 4 at servo connector. If battery voltage exists, replace stoplight switch. If battery voltage does not exist, go to next step. 8. Check Stoplight Circuit - Measure voltage on pin No. 4 at servo connector while depressing brake pedal. If battery voltage exists, go to step 12). If battery voltage does not exist, go to next step. 9. Check Stoplight Switch Resistance - Disconnect stoplight switch. Measure resistance across stoplight switch terminals while exercising switch. On probe, measure across terminals No. 1 and 4. If resistance is less than 5 ohms with brakes applied, go to next step. If resistance is greater than 5 ohms, with brakes applied, replace stoplight switch. 10. Check Power To Stoplight Switch - Disconnect stoplight switch harness connector. Check for battery voltage at stoplight switch Light Green/Red wire. If battery voltage exists, go to next step. If battery voltage does not exist, check for blown fuse or open circuit. Repair as necessary. 11. Check Stoplight Switch-To-Servo Circuit - Measure resistance between servo connector pin 19. Check Vehicle Speed Sensor (VSS) Circuit - Test drive vehicle. If speedometer is inoperative, diagnose and repair VSS or VSS circuit as necessary. See appropriate TESTS W/CODES article in ENGINE PERFORMANCE section. If speedometer operates okay, Disconnect harness connectors from VSS and servo. Measure resistance of wire between servo pin No. 3 and same color wire at VSS harness connector. If resistance is less than 5 ohms, go to next step. If resistance is greater than 5 ohms, repair open in VSS (servo pin No. 3) circuit. 20. Check For Broken Or Binding Servo Cable - Remove servo cable from servo. Check for broken or binding cable by pulling on cable ball slug. Replace cable as necessary. If cable is okay, replace servo. SET SPEED FLUCTUATES 1. Check Servo Cable & Throttle Linkage For Binding - Verify condition. Ensure engine is properly tuned. If condition occurs when cruise control is off, repair engine as required. If condition only occurs when cruise control is activated, check servo cable, throttle linkage, or throttle plate for binding or sticking. Repair as necessary. 2. Check Vehicle Speed Sensor - Unplug VSS connector. Measure resistance between VSS terminals. If resistance is not 200-300 ohms, replace VSS. If resistance is 200-300 ohms, check VSS circuit for open or short. If wiring is okay, go to next step. 3. Replace Servo - Substitute a known-good servo. Test drive vehicle and check for proper cruise control operation. If speed still fluctuates, check PCM for stored codes. See appropriate TESTS W/CODES article. SYSTEM DOES NOT DISENGAGE WHEN BRAKES ARE APPLIED 1. Check Deactivator Switch Circuit - Disconnect servo connector. Without brakes applied, measure voltage between servo connector pins No. 9 and 10. If battery voltage exists, go to next step. If battery voltage does not exist, repair deactivator circuit. See SYSTEM INOPERATIVE test. 2. Check Deactivator Switch Operation - Disconnect servo connector. Apply brakes. Measure voltage between servo connector pins No. 9 and 10. If battery voltage exists, replace deactivator switch. If battery voltage does not exist, go to next step. 3. Check Stoplight Switch - Unplug servo connector. With brakes applied, measure voltage between servo connector pins No. 4 and 10. See Fig. 1 . If battery voltage exists, go to next step. If battery voltage does not exist, replace brake switch, fuse, or repair open circuit. 4. Check For Binding Servo Cable - Remove servo cable from servo. Check for breaks or binding by pulling on cable ball slug. If throttle does not operate freely, check throttle plate operation. Replace cable if necessary. If cable is okay, replace servo assembly. COAST, RESUME OR OFF FUNCTION INOPERATIVE Unplug servo connector. Measure resistance between pins No. 5 and 6 of servo connector while depressing each function switch and rotating steering wheel. If all resistance readings are as specified, replace servo. See CONTROL SWITCH RESISTANCES table.

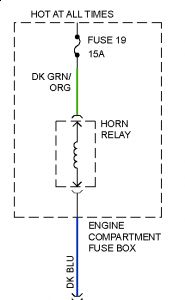

HORN Disconnect horn switch connector(s). Continuity should not exist between horn switch wires with horn button(s) released. Press horn button(s). Continuity should exist.

Saturday, September 5th, 2009 AT 12:11 PM