There is aslo a TSB on 5.4 for non commanded EGR flow, test like this: 5.4L 2V - INTERMITTENT ROUGH IDLE - NON-COMMANDED EGR FLOW TECHNICAL SERVICE BULLETIN Reference Number(s): 05-4-17, Â Date of Issue: Â March 7, 2005 Related Ref Number(s): 05-4-17 ARTICLE BEGINNING DESCRIPTION INTERMITTENT ROUGH IDLE - NON-COMMANDED EGR FLOW ISSUE Some 1997-2005 5.4L 2V vehicles may exhibit an intermittent rough idle. This may be due to non- commanded EGR flow. ACTION EGR flow can be detected by comparing the stabilized DPFEGR KOER voltage (from NGS/WDS) at idle after manually opening and closing the EGR valve through 8 cycles. Record the DPFEGR voltage after each cycle. If the DPFEGR voltage increases by 0.03V or more from the stabilized idle voltage and is associated with a rough idle, the valve should be replaced. Refer to the following Service Procedure. SERVICE PROCEDURE 1. Connect NGS/WDS and monitor DPFEGR PID. 2. Record initial stabilized DPFEGR voltage. 3. Disconnect the EGR valve vacuum line and connect hand held vacuum pump. 4. Raise RPM to prevent stalling and fully open the EGR valve. 5. Fully close valve and return to idle. 6. Record stabilized DPFEGR voltage. 7. Repeat Steps 4-6, eight (8) times. 8. If voltage increases by 0.03V or more with an associated rough idle condition during any of the cycles, the EGR valve may be sticking. Lightly tap the EGR valve casting and observe if voltage returns to initial DPFEGR value. a. If the DPFEGR voltage returns to the initial value and the associated rough idle is gone replace the EGR valve. b. If there is no change in DPFEGR voltage do not replace the EGR valve and perform normal diagnostics. FORD: 1997-1999 F-250 LD; 1997-2004 F-150; 1997-2005 E-Series; 1998-2004 Expedition; 1999-2004 F-Super Duty; 2000-2005 Excursion LINCOLN: 1998-1999 Navigator

9. If the EGR valve is replaced repeat Steps 3-6, two (2) times to verify fix. PARTS INFORMATION PARTS INFORMATION WARRANTY INFORMATION Part Number Part Name XL3Z-9D475-CA EGR Valve 4/5/2010 ... Fuel system:

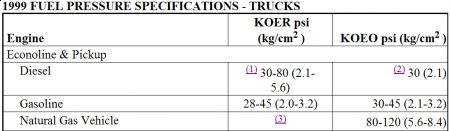

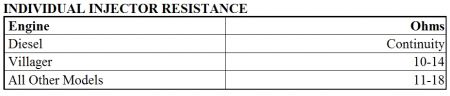

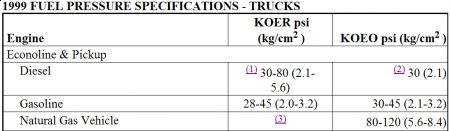

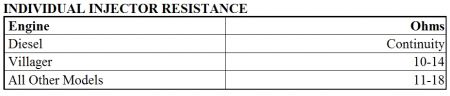

1. Release fuel pressure. Install fuel pressure gauge. Turn ignition on and read fuel pressure. Compare fuel pressure reading on fuel pressure gauge with specifications in FUEL PRESSURE SPECIFICATIONS . 2. If fuel pressure is not within specifications, check fuel pressure regulator. With engine running, connect hand vacuum pump and apply vacuum to regulator. 3. Ensure fuel pressure changes as vacuum at regulator is increased and decreased. If no pressure change occurs, replace regulator and recheck system. For additional testing information, go to TEST HC in SELF-DIAGNOSTICS - EEC-V or SELF-DIAGNOSTICS - VILLAGER article. FUEL INJECTORS Fuel Injector Resistance Disconnect injector harness connectors. Using digital ohmmeter, measure resistance between injector terminals. See INDIVIDUAL INJECTOR RESISTANCE table. Replace any injector not within specification. Fuel Injector Check (Gasoline) Start engine and allow to idle. If engine will not start, crank engine for 10 seconds. Using a stethoscope, listen for clicking sound at each injector. If clicking sound is heard, fuel injector is operating. If clicking sound is not heard, proceed as follows: Ã Â Â For all EEC-V models, go to step 8) of TEST HD in SELF-DIAGNOSTICS-EEC-V article. Ã Â Â For Villager, go to step 4) of TEST HD in SELF-DIAGNOSTICS-VILLAGER article. NOTE: For additional testing and information, see SYSTEM & COMPONENT TESTING - EEC-V article. Page 1 of 1 4/5/2010 ...

SPONSORED LINKS

Monday, April 5th, 2010 AT 3:24 PM