IGNITION SYSTEMS

Electronic Ignition (EI) System

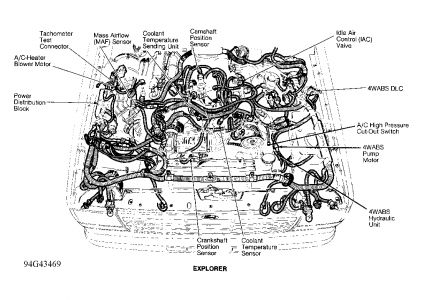

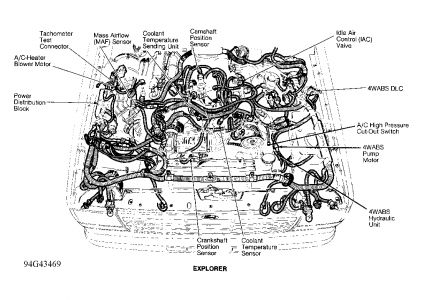

System is used on 4.0L engines and consists of a Variable Reluctance Sensor (VRS), an EI module, a PCM and one 6-tower coil pack.

During system operation, EI module receives crankshaft position information from VRS. In turn, EI module generates a Profile Ignition Pick-Up (PIP) signal and sends it to PCM. The PCM responds with a Spark Angle Word (SAW) signal containing advance or retard timing information which it sends to EI module. The EI module then processes VRS and SAW signals to decide which coils to fire. In addition, EI module generates an Ignition Diagnostic Monitor (IDM) signal and sends it to PCM, which uses it during failure mode to provide a tach output signal.

The EI module is a microprocessor and makes decisions about spark timing and coil firing. The EI module turns coils on and off at correct times and in proper sequence, based on VRS and SAW signals. The EI module, upon receiving VRS and SAW signals, produces PIP and IDM output signals and sends these signals to PCM.

The PCM receives IGN GND and PIP signals from EI module, and then generates a SAW output signal, based upon fuel, air and other sensor information. PCM also receives an IDM signal from EI ignition module to determine if a failure mode should be recorded.

The coil pack receives active low signals from EI module and fires 2 spark plugs at a time. One plug is for cylinder to be fired (on compression stroke), and other plug goes to mating cylinder (on exhaust stroke). The next time coil is fired, situation is reversed. Coils are fired according to engine firing order

The crankshaft position sensor and the camshaft position sensor both just screw out and screw back in (bolts)

SPONSORED LINKS

Tuesday, April 13th, 2021 AT 10:04 AM