Welcome to 2CarPros.

I don't think anything like this resulted from what you did. Based on your description, it sounds like a bad crankshaft position sensor. When they start going bad, they will fail when hot. Take a look through these links:

https://www.2carpros.com/articles/how-a-crank-shaft-angle-sensor-works

https://www.2carpros.com/articles/symptoms-of-a-bad-crankshaft-sensor

https://www.2carpros.com/articles/crankshaft-angle-sensor-replacement

Now, if you feel the symptoms you experience mirror what is listed above under symptoms, then we need to confirm that is the issue because on this vehicle, the timing belt needs removed to replace the sensor.

Interestingly, a bad sensor may or may not set the check engine light to come on, so depending on trouble codes may provide a false positive. So, what I suggest is this. You need to get your hands on a live data scanner. With the scanner, see if the crank signal is lost or if the RPM signal is lost when the engine dies and won't restart. If the signal is lost, then most likely the sensor is bad.

___________________________________

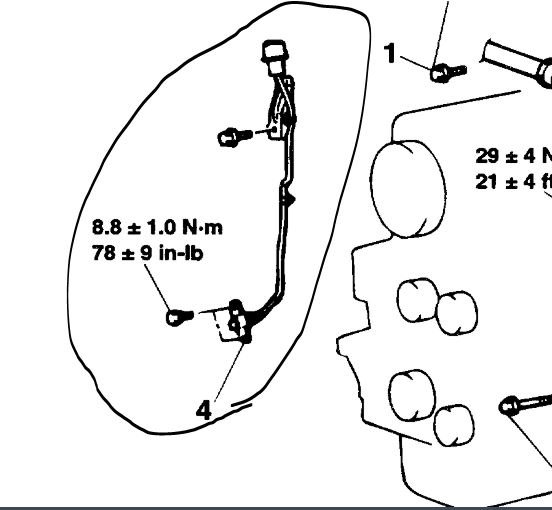

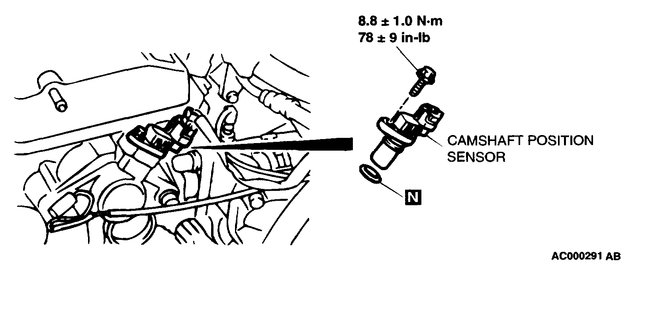

Here are the directions for removal and replacement of the timing belt. I'm adding them if you determine this is the problem. All attached pictures correlate with the directions. The first picture I attached shows the crankshaft position sensor.

__________________________________

2003 Mitsubishi Eclipse L4-2.4L SOHC

Timing Belt A (Main Belt)

Vehicle Engine, Cooling and Exhaust Engine Timing Components Timing Belt Service and Repair Removal and Replacement Timing Belt A (Main Belt)

TIMING BELT A (MAIN BELT)

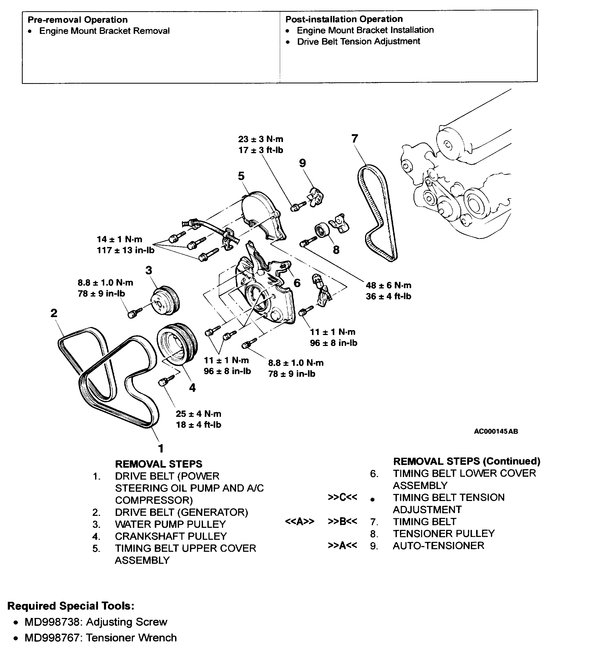

pic 2

REMOVAL AND INSTALLATION

REMOVAL SERVICE POINT

[[A]] TIMING BELT REMOVAL

CAUTION: The crankshaft should always be turned in the forward direction only.

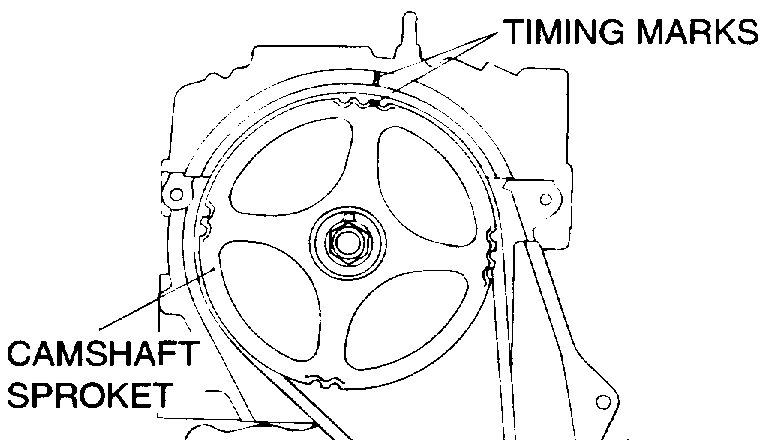

pic 3

1. Turn the crankshaft in the forward direction (to the right) to align the camshaft sprocket timing marks.

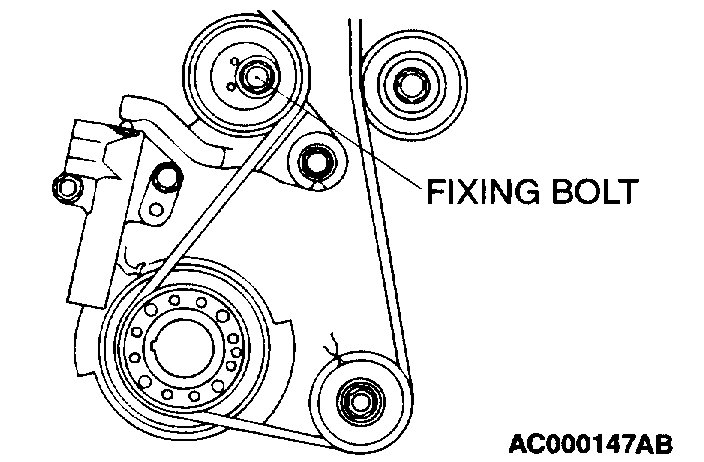

pic 4

2. Loosen the tension pulley fixing bolt.

CAUTION: If the timing belt is to be re-used, use chalk to mark (on its flat side) an arrow indicating the clockwise direction.

3. Move the tension pulley to the water pump side, and then remove the timing belt.

INSTALLATION SERVICE POINTS

]]A[[ AUTO-TENSIONER INSTALLATION

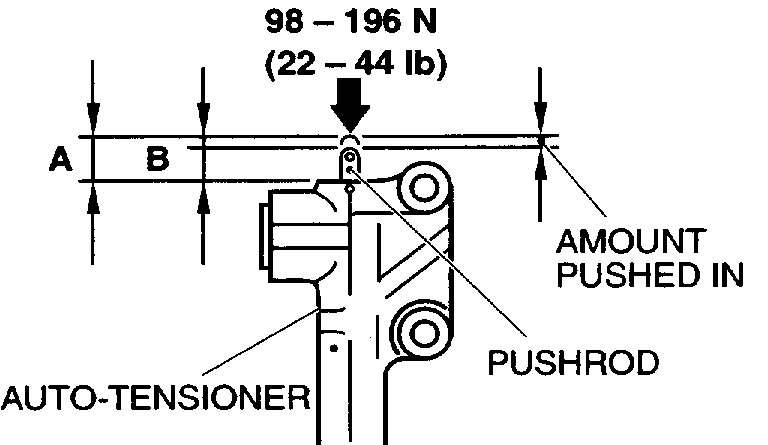

pic 5

1. Apply 98 - 196 N (22 - 44 pound) force to the pushrod of the auto-tensioner by pressing it against a metal object (such as the engine block) and measure the movement of the pushrod.

Standard value: Within 1 mm (0.04 inch)

A: Length when it is free (not pressed)

B: Length when it is pressed

A-B: Movement

2. If it is outside the standard value, replace the auto-tensioner.

CAUTION: Never compress the pushrod too fast, or it may be damaged.

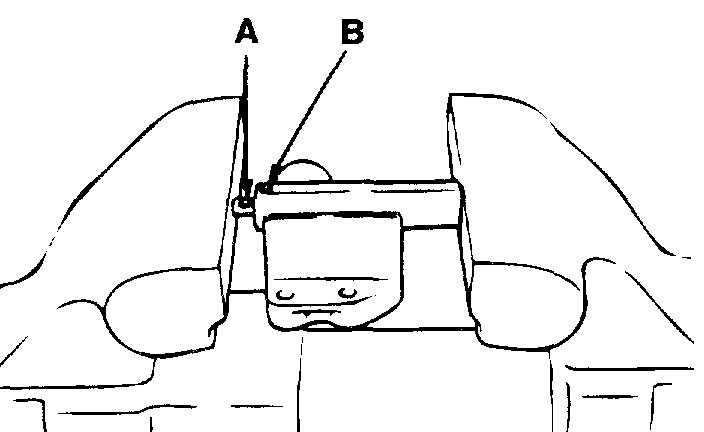

pic 6

3. Use a press or vise to gently compress the auto-tensioner pushrod until pin hole A of the pushrod and pin hole B of the tensioner cylinder are aligned.

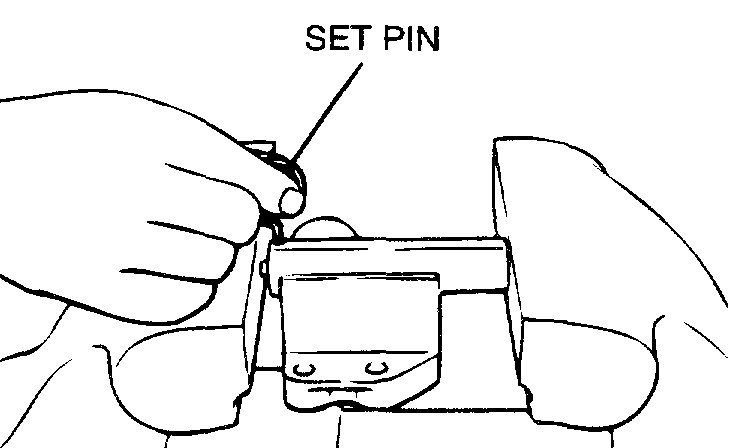

pic 7

4. When the holes are aligned, insert the set pin.

NOTE: When replacing the auto-tensioner with a new part, the pin will be in the auto-tensioner.

5. Install the auto-tensioner to the engine.

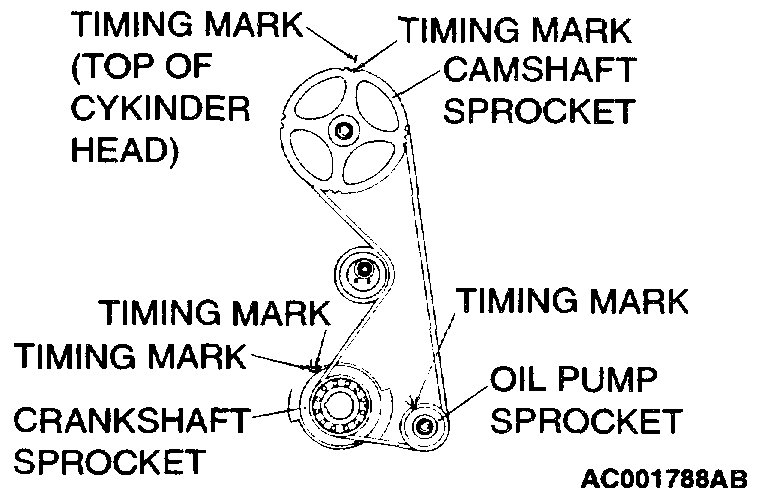

]]B[[ TIMING BELT INSTALLATION

pic 8

1. Align the timing marks on the camshaft sprocket, crankshaft sprocket and oil pump sprocket.

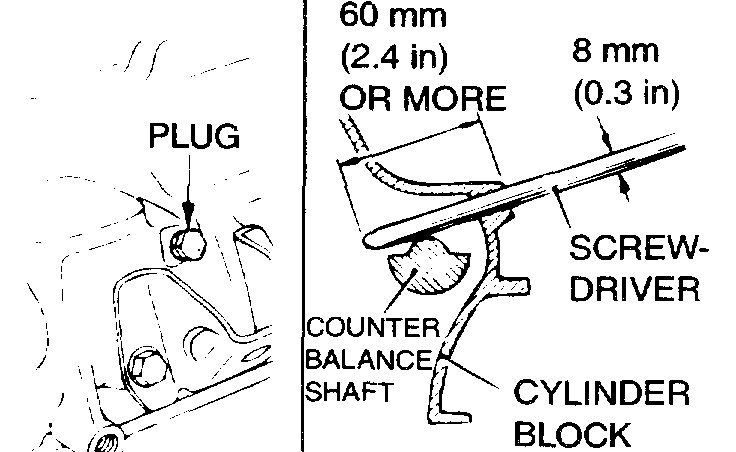

pic 9

2. After aligning the timing mark on the oil pump sprocket, remove the cylinder block plug and insert a Phillips) head 8 mm (0.3 inch) screwdriver. Check to be sure that the screwdriver goes in 60 mm (2.4 inches) or more. If the screwdriver will only go in 20 - 25 mm (0.8 - 1.0 inch) before striking the counterbalance shaft, turn the sprocket once, realign the timing marks and check that the screwdriver goes in 60 mm (2.4 inches) or more. The screwdriver should not be taken out until the timing belt is installed.

CAUTION: If the timing belt is re-used, install so that the arrow marked on it at time of removal is pointing in the clockwise direction.

3. Install the belt to the crankshaft sprocket, oil pump sprocket and camshaft sprocket in that order, so that there is no slackness in the belt tension.

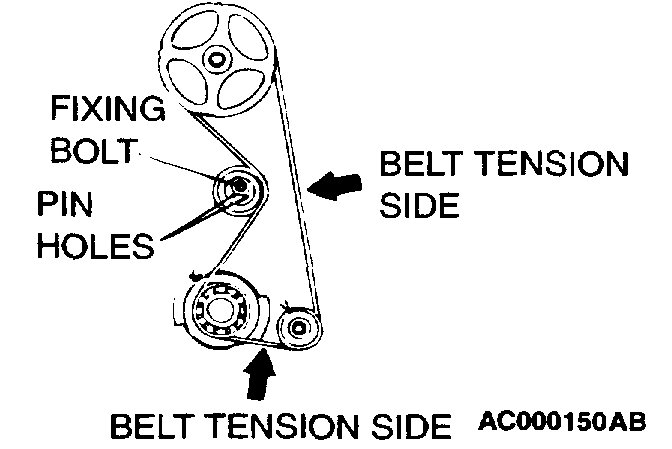

pic 10

4. Set the tension pulley so that the pin holes are at the bottom, press the tension pulley lightly against the timing belt, and then provisionally tighten the fixing bolt.

5. Adjust the timing belt tension.

]]C[[ TIMING BELT TENSION ADJUSTMENT

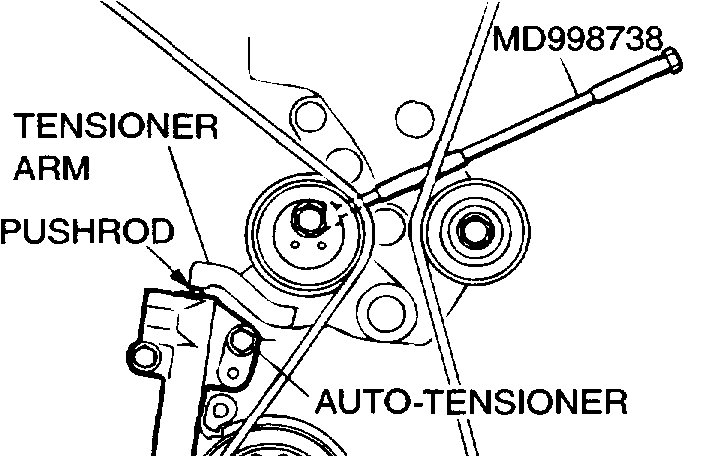

CAUTION: Do not use a spanner or the similar tool to turn special tool MD998738. Otherwise, the auto-tensioner set pin may be broken. Turn special tool MD998738 by hand only.

pic 11

1. Remove the rubber plug from the rear of the timing belt cover assembly. Then screw in special tool MD998738 by hand until the tensioner arm is touching the auto-tensioner pushrod.

2. After turning the crankshaft 1/4 of a revolution in the counterclockwise direction, turn it in the clockwise direction until the timing marks are aligned.

CAUTION: When tightening the fixing bolt, make sure that the tension pulley does not turn with the bolt.

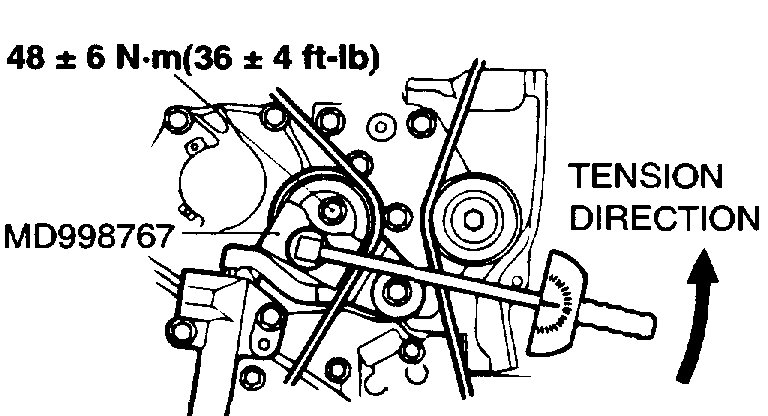

pic 12

3. Loosen the tension pulley fixing bolt, and then use special tool MD998767 and a torque wrench to tighten the fixing bolt to the specified torque while applying tension to the timing belt.

Timing belt tension torque: 3.5 Nm (31 inch lbs.)

Tightening torque: 48 ± 6 Nm (36 ± 4 ft. lbs.)

4. Remove the set pin that has been inserted into the auto-tensioner, and then remove special tool MD998767.

pic 13

5. Turn the crankshaft two revolutions clockwise so that the timing marks are aligned. After leaving it for 15 minutes, measure the amount of protrusion of the auto-tensioner.

Standard value (A): 3.8 - 4.5 mm (0.15 - 0.18 inch)

6. If the amount of protrusion is outside the standard value, repeat steps (1) through (5).

7. Check again to be sure that the timing marks of each sprocket are aligned.

________________________________________________

2003 Mitsubishi Eclipse L4-2.4L SOHC

Timing Belt B (Silent Shaft Belt)

Vehicle Engine, Cooling and Exhaust Engine Timing Components Timing Belt Service and Repair Removal and Replacement Timing Belt B (Silent Shaft Belt)

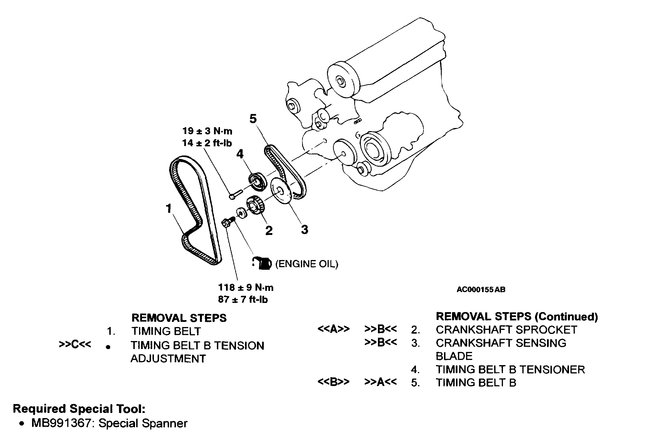

TIMING BELT B (SILENT SHAFT BELT)

pic 14

imageOpen In New TabZoom/Print

REMOVAL AND INSTALLATION

REMOVAL SERVICE POINTS

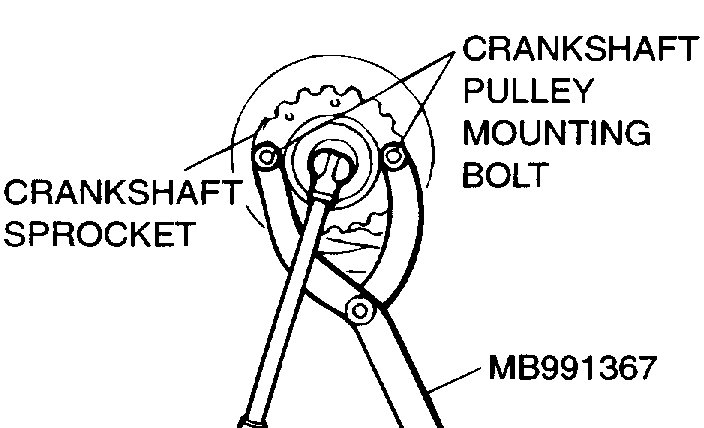

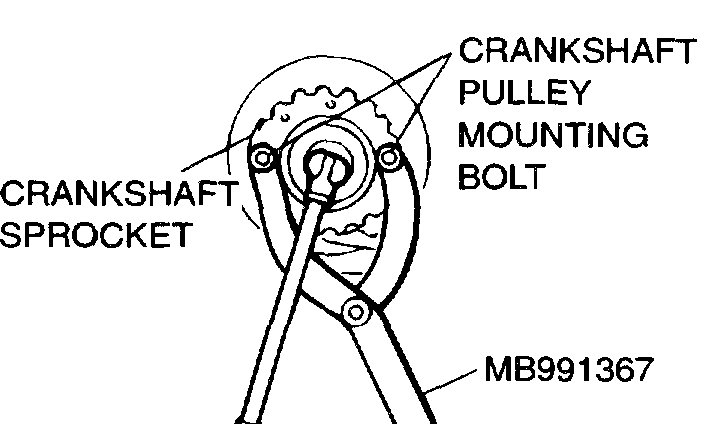

[[A]] CRANKSHAFT SPROCKET REMOVAL

pic 15

1. Use the crankshaft pulley mounting bolt to hold special tool MB991367.

2. Loosen the crankshaft sprocket mounting bolt, and remove the sprocket.

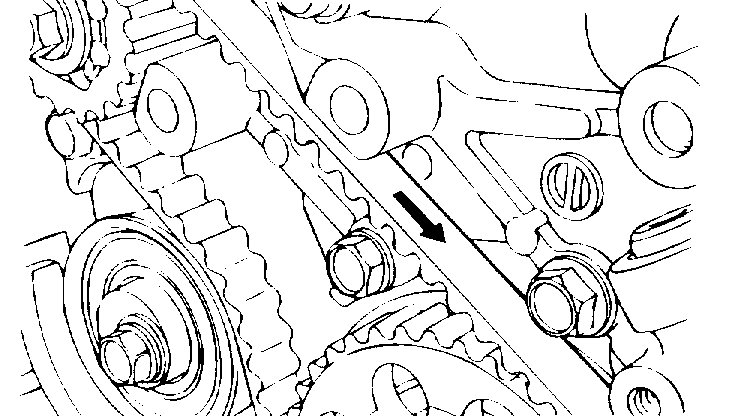

[[B]] TIMING BELT B REMOVAL

pic 16

CAUTION: If the belt is to be re-used, mark an arrow on the belt with chalk indicating the clockwise direction of rotation.

INSTALLATION SERVICE POINTS

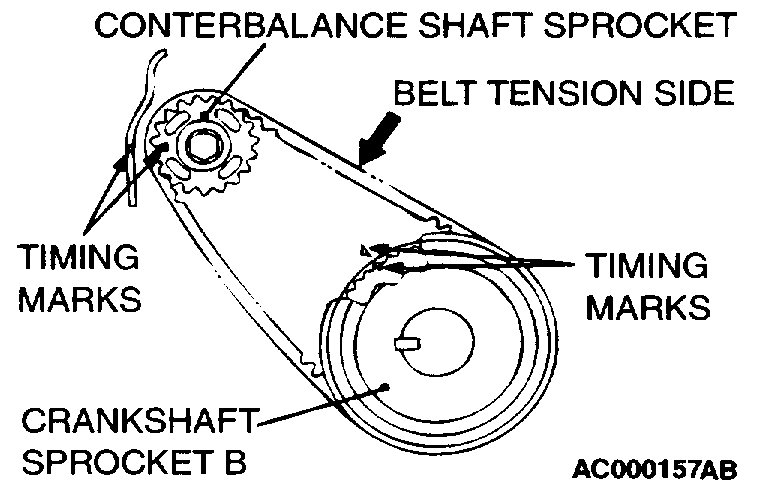

]]A[[ TIMING BELT B INSTALLATION

pic 17

1. Ensure that crankshaft sprocket B timing marks and the counterbalance shaft sprocket timing marks are aligned.

2. Fit timing belt B over crankshaft sprocket B and the counterbalance shaft sprocket. Ensure that there is no slack in the belt.

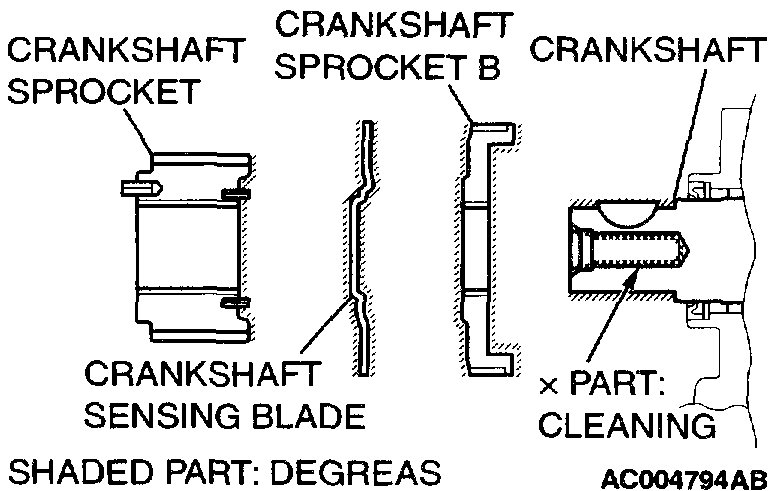

]]B[[ CRANKSHAFT SENSING BLADE/CRANKSHAFT SPROCKET INSTALLATION

pic 18

1. To prevent the crankshaft bolt from loosening, degrease or clean the seating surfaces of the crankshaft, crankshaft sprocket B. crankshaft sensing blade and crankshaft at the shown positions.

2. Install the crankshaft sensing blade so that they face as shown in the illustration.

3. Apply the minimum amount of engine oil to the seat surface and thread of the crankshaft bolt.

pic 19

4. Use the crankshaft pulley mounting bolt to secure special tool MB991367.

5. Tighten the crankshaft sprocket bolt to the specified torque.

Tightening torque: 118 ± 9 Nm (87 ± 7 ft. lbs.)

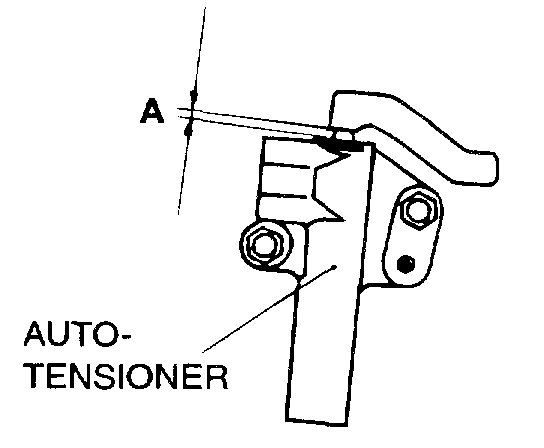

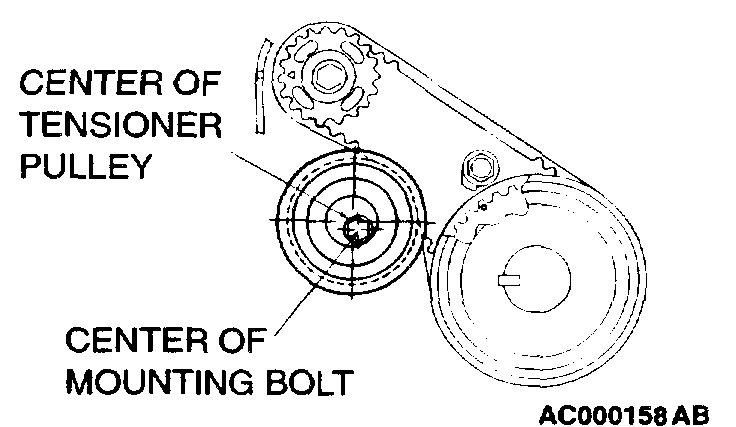

]]C[[ TIMING BELT B TENSION ADJUSTMENT

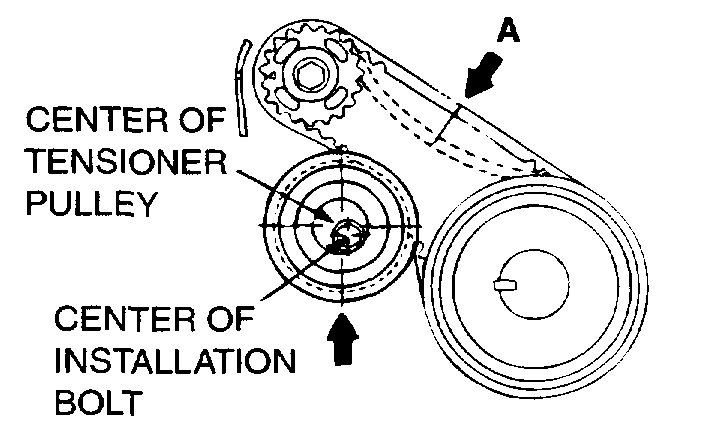

pic 20

1. Temporarily fix the timing belt B tensioner so the center of the tensioner pulley is to the left and above the center of the mounting bolt. Temporarily attach the tensioner pulley so the flange is toward the front of the engine.

CAUTION: When tightening the bolt, ensure that the tensioner pulley shaft does not rotate with the bolt. Allowing it to rotate with the bolt can cause excessive tension of the bolt.

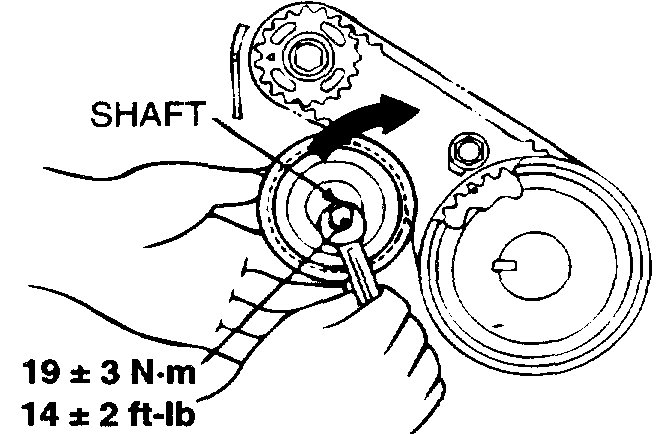

pic 21

2. Holding the timing belt B tensioner up with your finger in the direction of the arrow, apply pressure on the timing belt so the tension side of the belt is taut. Now tighten the bolt to fix the tensioner.

Tightening torque: 19 ± 3 Nm (14 ± 2 ft. lbs.)

pic 22

3. To ensure that the tension is correct, depress the belt (point A) with a finger. Adjust the belt tension if it is incorrect.

Standard value: 5 - 7 mm (0.2 - 0.3 inch)

_______________________________

Let me know if this helps. Also, if you find this needs done, it would be a good time to replace the belts and tensoiners.

Let me know if you have other questions.

Take care,

Joe

Images (Click to make bigger)

Wednesday, August 21st, 2019 AT 8:01 PM