Hello

I would replace the ignition switch with a new one

I think the last part, the customer programming will help you......

Now when you say you ". . .burned the . . ." you did what it says here for a new key?

In addition to having to be cut to match the mechanical coding of the ignition and door lock cylinders and programmed for operation of the RKE system, each new key has a unique transponder identification code that is permanently programmed into it by the manufacturer, and which must be programmed into the Electronic Ignition Switch (EIS) (also known as the Electronic Ignition Switch/Central GateWay/EIS/CGW or EZS) to be recognized by the vehicle immobilizer system as a valid key.

So you have done this. . .. . .. . ..

Since it appears it is not seeing the RF signal that is what I am wondering about the programming. . .. . ...from what it says it has a secret code programmed into the transmitter key and the EIS by the manufacture. . .. . ...it is something you can not do. . .. . .. . .. . .is that what you see?

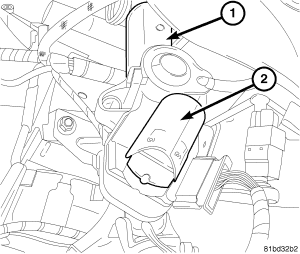

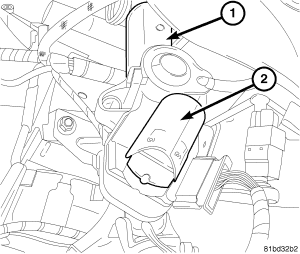

SHAFT LOCK MODULE

Fig. 6: Shaft Lock Module

Courtesy of CHRYSLER LLC

A shaft lock module (2) is located on the lower end of the steering column housing (1) below the instrument panel in the passenger compartment of the vehicle. This unit is designed to work in conjunction with the Electronic Ignition Switch (EIS) (also known as the Electronic Ignition Switch/Central GateWay/EIS/CGW or EZS) to control a locking bolt that engages a machined slot in the steering shaft to prevent shaft rotation whenever the ignition switch is in the 0 (OFF) position or a valid key is not present in the ignition lock cylinder on the instrument panel.

Concealed within the die cast aluminum shaft lock module housing is the electronic circuitry of the module, a bi-directional electric motor and the locking bolt. The module is connected through an integral connector receptacle to the vehicle electrical system through a take out and connector of the vehicle wire harness. The mounting provisions for the shaft lock module are designed to resist tampering. The module cannot be removed from the steering column without damaging the column.

The shaft lock module unit cannot be adjusted or repaired and, if ineffective or damaged, it must be replaced as a unit with the steering column.

OPERATION

SHAFT LOCK MODULE

The electronic circuitry within the shaft lock module contains all of the logic circuits and components to monitor and control the operation of the shaft locking bolt. The module uses a serial data bus for bi-directional communication with the Electronic Ignition Switch (EIS) (also known as the Electronic Ignition Switch/Central GateWay/EIS/CGW or EZS). If the module detects a problem with the positioning or operation of the locking bolt, it sends an error message to the EIS, which then stores a Diagnostic Trouble Code (DTC).

The shaft lock module continuously monitors inputs from the EIS and energizes the electric motor to move the locking bolt to the locked or unlocked position based upon that input. If the EIS indicates that the key present in the ignition lock cylinder is invalid, the locking bolt remains in the locked position. When the EIS indicates that a valid key is present in the ignition lock cylinder, the shaft lock module operates a motor to move the locking bolt to the unlocked position. However, to prevent inadvertent column locking due to a failure while the vehicle is being operated, the module cannot move the locking bolt from the unlocked position to the locked position as long as the ignition is not turned to the 0 (OFF) position.

The shaft lock module receives ground at all times through a hard wired remote ground point. The module receives battery voltage to move the locking bolt only when the ignition switch is in the 0 (OFF) position.

The hard wired inputs to the shaft lock module may be diagnosed using conventional diagnostic tools and procedures. Refer to the appropriate wiring information. However, conventional diagnostic methods will not prove conclusive in the diagnosis of the shaft lock module or the electronic controls or communication between other modules and devices that provide some features of the steering shaft lock control. The most reliable, efficient, and accurate means to diagnose the shaft lock module or the electronic controls and communication related to shaft lock module operation requires the use of a diagnostic scan tool. Refer to the appropriate diagnostic information.

TRANSMITTER KEY

DESCRIPTION

TRANSMITTER KEY

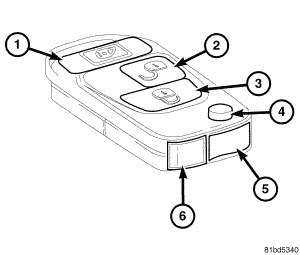

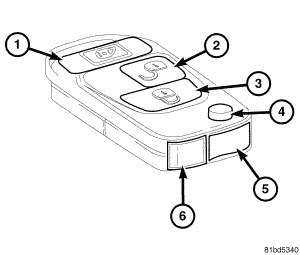

Fig. 10: Transmitter Key

Courtesy of CHRYSLER LLC

Each key used in this vehicle consists of both an electronic key and a mechanical key that folds away into the key cover. The electronic key includes a transponder chip on the circuit board beneath the cover of the integral Remote Keyless Entry (RKE) radio transmitter. In addition to having to be cut to match the mechanical coding of the ignition and door lock cylinders and programmed for operation of the RKE system, each new key has a unique transponder identification code that is permanently programmed into it by the manufacturer, and which must be programmed into the Electronic Ignition Switch (EIS) (also known as the Electronic Ignition Switch/Central GateWay/EIS/CGW or EZS) to be recognized by the vehicle immobilizer system as a valid key.

The key includes the following features:

"� Battery and Function Indicator (6)

"� LOCK Transmitter Button (3)

"� Mechanical Key (5) - Storage position.

"� Key Release Button (4) - Mechanical key release.

"� UNLOCK Transmitter Button (2)

"� UNLOCK Rear Door/Sliding Door Button (1) - Optional on some vehicles.

The vehicle immobilizer transponder cannot be adjusted or repaired. If ineffective or damaged, the entire key and RKE transmitter unit must be replaced.

OPERATION

TRANSMITTER KEY

When the transmitter key is inserted into the ignition lock cylinder, the Electronic Ignition Switch (EIS) (also known as the Electronic Ignition Switch/Central GateWay/EIS/CGW or EZS) communicates through an induction coil and antenna with the key transponder using a Radio Frequency (RF) signal. The EIS then listens for a RF response from the transponder through the same antenna. The key transponder chip is within the range of the EIS transceiver antenna ring when it is inserted into the ignition lock cylinder. The EIS determines whether a valid key is present in the ignition lock cylinder based upon the response from the transponder. If a valid key is detected, the EIS allows ignition switch position to be recognized and communicated to other electronic modules over the Controller Area Network (CAN) data bus, which will allow the engine to be started. If the EIS detects an invalid key, it will not allow changes in the ignition switch position to be communicated to other modules, and the vehicle cannot be operated.

Each transmitter key has a unique transponder identification code permanently programmed into it by the manufacturer. Likewise, the EIS has a unique Secret Key code programmed into it by the manufacturer. When a transmitter key is programmed into the memory of the EIS, the EIS stores the transponder identification code from the key, and the key learns the Secret Key code from the EIS. Once the key learns the Secret Key code of the EIS, it is permanently stored in the memory of the transponder. Therefore, once a key has been programmed to a particular vehicle, it cannot be used on any other vehicle. See STANDARD PROCEDURE.

The EIS performs a self-test of the vehicle immobilizer system each time the ignition switch is turned to the 1 (ON) position, and will store key-related fault information in the form of a Diagnostic Trouble Code (DTC) in EIS memory if a key transponder problem is detected. The transmitter key transponder chip can be diagnosed, and any stored DTC can be retrieved using a diagnostic scan tool. Refer to the appropriate diagnostic information.

Now what I have found is how the customer can program the key. . .. . .. . .have you done the below?

STANDARD PROCEDURE

SENTRY KEY TRANSPONDER PROGRAMMING

All Sentry Keys included with the vehicle are pre-programmed to work with the Sentry Key Immobilizer System (SKIS) when it is shipped from the factory. The Sentry Key REmote Entry Module (SKREEM) (also known as the Wireless Control Module/WCM) may be programmed to recognize up to a total of eight Sentry Keys. When programming a blank Sentry Key transponder, the key must first be cut to match the ignition switch lock cylinder in the vehicle for which it will be used. Once the additional or new key has been cut, the SKREEM must be programmed to recognize it as a valid key. There are two possible methods to program the SKREEM to recognize a new or additional valid key, the Secured Access Method and the Customer Learn Method. Following are the details of these two programming methods.

SECURED ACCESS METHOD

The Secured Access method applies to all vehicles.

This method requires the use of a diagnostic scan tool. This method will also require that you have access to the unique four-digit PIN code that was assigned to the original SKREEM. The PIN code must be used to enter the Secured Access Mode in the SKREEM. This PIN number may be obtained from the vehicle owner, from the original vehicle invoice, or from the DaimlerChrysler Customer Center. Refer to STANDARD PROCEDURE .

CUSTOMER LEARN METHOD

NOTE: The Customer Learn feature is only available on domestic vehicles, or those vehicles which have a U.S. country code designator. This programming method also requires access to at least two valid Sentry Keys. If two valid Sentry Keys are not available, or if the vehicle does not have a U.S. country code designator, the Secured Access Method MUST be used to program new or additional valid keys to the SKREEM.

The Customer Learn programming method procedures are as follows:

1. Obtain the blank Sentry Key(s) that are to be programmed as valid keys for the vehicle. Cut the blank key(s) to match the ignition switch lock cylinder mechanical key codes.

2. Insert one of the two valid Sentry Keys into the ignition switch and turn the ignition switch to the ON position.

3. After the ignition switch has been in the ON position for longer than 3 seconds, but no more than 15 seconds, cycle the ignition switch back to the OFF position. Replace the first valid Sentry Key in the ignition switch lock cylinder with the second valid Sentry Key and turn the ignition switch back to the ON position. The second valid Sentry Key must be inserted in the lock cylinder within 15 seconds of removing the first valid key.

4. About 10 seconds after the completion of step 3, the security indicator in the instrument cluster will start to flash and a single audible chime will sound to indicate that the system has entered the Customer Learn programming mode.

5. Within 60 seconds of entering the Customer Learn programming mode, turn the ignition switch to the OFF position, replace the valid Sentry Key with a blank Sentry Key transponder, and turn the ignition switch back to the ON position.

6. About 10 seconds after the completion of step 5, a single audible chime will sound and the security indicator will stop flashing, stay ON solid for 3 seconds, then turn OFF to indicate that the blank Sentry Key has been successfully programmed. The SKIS will immediately exit the Customer Learn programming mode. After the ignition is cycled the vehicle may be started using the newly programmed valid Sentry Key.

Each of these steps must be repeated and completed in their entirety for each additional Sentry Key that is to be programmed. If the above steps are not completed in the given sequence, or within the allotted time, the SKIS will exit the Customer Learn programming mode and the programming will be unsuccessful. The SKREEM will also automatically exit the Customer Learn programming mode if it sees a non-blank Sentry Key transponder when it should see a blank, if it has already programmed 8 valid Sentry Keys, or if the ignition switch is turned to the OFF position for more than about 50 seconds.

NOTE: If an attempt is made to start the vehicle while in the Customer Learn mode (security indicator flashing), the SKIS will respond as though the vehicle were being started with an invalid key. In other words, the engine will stall after about two seconds of operation. No faults will be set.

NOTE: Once a Sentry Key has been programmed as a valid key to a vehicle, it cannot be programmed as a valid key for use on any other vehicle.

Let me know if the above helps. . .. . .. . ...

Thanks and hope you have a great day.

Images (Click to make bigger)

Friday, November 17th, 2017 AT 7:00 PM