Hello

It could be one of a couple of things. Fuel pressure bleeding past the fuel injectors. Fuel pressure bleed past the check valve in the module.

I have attached information on how you can perform a some checks.

Also if you do need to get back with us ensure you provide your specific engine Liter size and the 8th digit in your VIN.

Sorry, you will have to drop the tank to change the pump if bad.

Also, please go to Auto Zone or O'Reilly's and for free they can pull the codes to the car. Most important. Once they check your codes, if they find something and you don't get it fixed and need to get back with us, please make sure you tell us exactly what the code was, number and all. Example, if the code was E0568 O2 Sensor bad. Then make sure you give us all of that. While there for free also they can bring their tester out and check your battery, alternator and starter.

Thank you very much for the donation.

Find a car repair manual for your car repair questions.

Fuel Pump

The electric fuel pump is located inside of the fuel pump module. A 12 volt , permanent magnet, electric motor powers the fuel pump. The electric fuel pump is not a separate, serviceable component.

Voltage to operate the electric pump is supplied through the fuel pump relay

Fuel is drawn in through a filter at the bottom of the module and pushed through the electric motor gearset to the pump outlet.

Check Valve Operation: The bottom section of the fuel pump module contains a one-way check valve to prevent fuel flow back into the tank and to maintain fuel supply line pressure (engine warm) when pump is not operational. It is also used to keep the fuel supply line full of gasoline when pump is not operational. After the vehicle has cooled down, fuel pressure may drop to 0 psi (cold fluid contracts), but liquid gasoline will remain in fuel supply line between the check valve and fuel injectors. Fuel pressure that has dropped to 0 psi on a cooled down vehicle (engine OFF) is a normal condition. Refer to the Fuel Pressure Leak Down Test for more information.

The electric fuel pump is not a separate, serviceable component

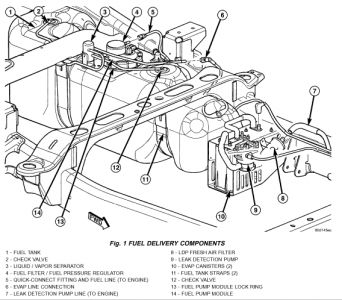

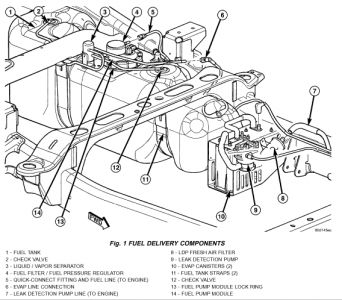

The fuel pump module assembly is located on the top of the fuel tank (Fig 1). The complete assembly contains the following components:

A combination fuel filter/fuel pressure regulator

A separate fuel pick-up, or inlet filter

An electric fuel pump

A lockring to retain pump module to tank

A soft gasket between tank flange and module

A fuel gauge sending unit (fuel level sensor)

Fuel line connection

The fuel gauge sending unit may be serviced separately. If the electrical fuel pump, primary inlet filter, fuel filter or fuel pressure regulator require service, the fuel pump module must be replaced.

Refer to Fuel Pump, Inlet Filter, Fuel Filter / Fuel Pressure Regulator and Fuel Gauge Sending Unit.

Fuel Pump Pressure Test

Use this test in conjunction with the Fuel Pump Capacity Test, Fuel Pressure Leak Down Test and Fuel Pump Amperage Test found elsewhere in this group.

Check Valve Operation: The fuel pump module contains a one-way check valve to prevent fuel flow back into the tank and to maintain fuel supply line pressure (engine warm) when pump is not operational. It is also used to keep the fuel supply line full of gasoline when pump is not operational. After the vehicle has cooled down, fuel pressure may drop to 0 psi (cold fluid contracts), but liquid gasoline will remain in fuel supply line between the check valve and fuel injectors. Fuel pressure that has dropped to 0 psi on a cooled down vehicle (engine OFF) is a normal condition. When the electric fuel pump is activated, fuel pressure should immediately (1 - 2 seconds) rise to specification.

The fuel system is equipped with a combination fuel filter / fuel pressure regulator. The fuel pressure regulator is not controlled by engine vacuum.

WARNING: THE FUEL SYSTEM IS UNDER CONSTANT FUEL PRESSURE EVEN WITH THE ENGINE OFF. BEFORE DISCONNECTING FUEL LINE AT FUEL RAIL, THIS PRESSURE MUST BE RELEASED. REFER TO THE FUEL SYSTEM PRESSURE RELEASE PROCEDURE.

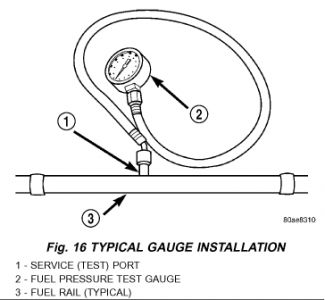

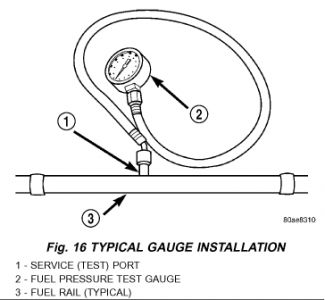

Remove protective cap at fuel rail test port. Connect the 0 - 414 kPa (0 - 60 psi) fuel pressure gauge (from gauge set 5069) to test port pressure fitting on fuel rail (Fig. 16). The DRB(R) III Scan Tool along with the PEP module, the 500 psi pressure transducer, and the transducer-to-test port adapter may also be used in place of the fuel pressure gauge.

Start and warm engine and note pressure gauge reading. Fuel pressure should be 339 kPa ±34 kPa (49.2 psi ±5 psi) at idle.

If engine runs, but pressure is below 44.2 psi , check for a kinked fuel supply line somewhere between fuel rail and fuel pump module. If line is not kinked, but specifications for either the Fuel Pump Capacity, Fuel Pump Amperage or Fuel Pressure Leak Down Tests were not met, replace fuel pump module. Refer to Fuel Pump Module Removal/Installation.

If operating pressure is above 54.2 psi , electric fuel pump is OK, but fuel pressure regulator is defective. Replace fuel pump module. Refer to Fuel Pump Module Removal/Installation.

Install protective cap to fuel rail test port.

Fuel Pump Capacity Test

Before performing this test, verify fuel pump pressure. Refer to Fuel Pump Pressure Test. Use this test in conjunction with the Fuel Pressure Leak Down Test.

Release fuel system pressure. Refer to Fuel Pressure Release Procedure.

Disconnect fuel supply line at fuel rail. Refer to Quick-Connect Fittings. Some engines may require air cleaner housing removal before line disconnection.

Obtain correct Fuel Line Pressure Test Adapter Tool Hose. Tool number 6539 is used for 5/16" fuel lines and tool number 6631 is used for 3/8" fuel lines.

Connect correct Fuel Line Pressure Test Adapter Tool Hose into disconnected fuel supply line. Insert other end of Adaptor Tool Hose into a graduated container.

Remove fuel fill cap.

To activate fuel pump and pressurize system, obtain DRB(R) scan tool and actuate ASD Fuel System Test.

A good fuel pump will deliver at least 1/10 liter of fuel in 7 seconds . Do not operate fuel pump for longer than 7 seconds with fuel line disconnected as fuel pump module reservoir may run empty.

If capacity is lower than specification, but fuel pump can be heard operating through fuel fill cap opening, check for a kinked/damaged fuel supply line somewhere between fuel rail and fuel pump module.

If line is not kinked/damaged, and fuel pressure is OK, but capacity is low, replace fuel pump module. Refer to Fuel Pump Module Removal/Installation for additional information.

If both fuel pressure and capacity are low, replace fuel pump module. Refer to Fuel Pump Module Removal/Installation.

FUEL PRESSURE LEAK DOWN TEST

Use this test in conjunction with the Fuel Pump Pressure Test and Fuel Pump Capacity Test.

Check Valve Operation: The electric fuel pump outlet contains a one-way check valve to prevent fuel flow back into the tank and to maintain fuel supply line pressure (engine warm) when pump is not operational. It is also used to keep the fuel supply line full of gasoline when pump is not operational. After the vehicle has cooled down, fuel pressure may drop to 0 psi (cold fluid contracts), but liquid gasoline will remain in fuel supply line between the check valve and fuel injectors. Fuel pressure that has dropped to 0 psi on a cooled down vehicle (engine OFF) is a normal condition. When the electric fuel pump is activated, fuel pressure should immediately (1 - 2 seconds) rise to specification.

Abnormally long periods of cranking to restart a hot engine that has been shut down for a short period of time may be caused by:

Fuel pressure bleeding past a fuel injector(s).

Fuel pressure bleeding past the check valve in the fuel pump module.

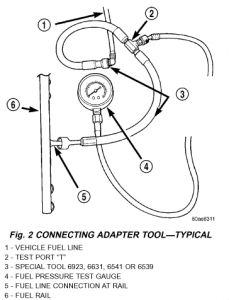

Disconnect the fuel inlet line at fuel rail. Refer to Quick Connect Fittings for procedures. On some engines, air cleaner housing removal may be necessary before fuel line disconnection.

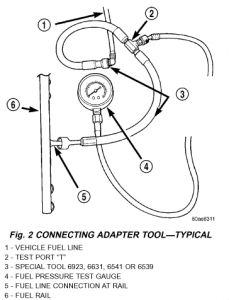

Obtain correct Fuel Line Pressure Test Adapter Tool Hose. Tool number 6539 is used for 5/16" fuel lines and tool number 6631 is used for 3/8" fuel lines.

Connect correct Fuel Line Pressure Test Adapter Tool Hose between disconnected fuel line and fuel rail (Fig. 2).

Connect the 0 - 414 kPa (0 - 60 psi) fuel pressure test gauge (from Gauge Set 5069) to the test port on the appropriate Adaptor Tool. The DRB(R) III Scan Tool along with the PEP module, the 500 psi pressure transducer, and the transducer-to-test port adapter may also be used in place of the fuel pressure gauge. The fittings on both tools must be in good condition and free from any small leaks before performing the proceeding test.

Start engine and bring to normal operating temperature.

Observe test gauge. Normal operating pressure should be 339 kPa ±34 kPa (49.2 psi ±5 psi) .

Shut engine off.

Pressure should not fall below 30 psi for five minutes .

If pressure falls below 30 psi , it must be determined if a fuel injector, the check valve within the fuel pump module, or a fuel tube/line is leaking.

Again, start engine and bring to normal operating temperature.

Shut engine off.

Testing for fuel injector or fuel rail leakage: Clamp off the rubber hose portion of Adaptor Tool between the fuel rail and the test port "T" on Adapter Tool. If pressure now holds at or above 30 psi , a fuel injector or the fuel rail is leaking.

Testing for fuel pump check valve, filter, regulator check valve or fuel tube/line leakage: Clamp off the rubber hose portion of Adaptor Tool between the vehicle fuel line and test port "T" on Adapter Tool. If pressure now holds at or above 30 psi , a leak may be found at a fuel tube/line. If no leaks are found at fuel tubes or lines, one of the check valves in either the electric fuel pump, fuel filter or fuel pressure regulator may be leaking. NOTE: A quick loss of pressure usually indicates a defective check valve in the pressure regulator. A slow loss of pressure usually indicates a defective check valve in the bottom of the fuel pump module. The check valves are not serviced separately Also, the electric fuel pump is not serviced separately.

Tuesday, November 4th, 2008 AT 10:31 PM