Hi,

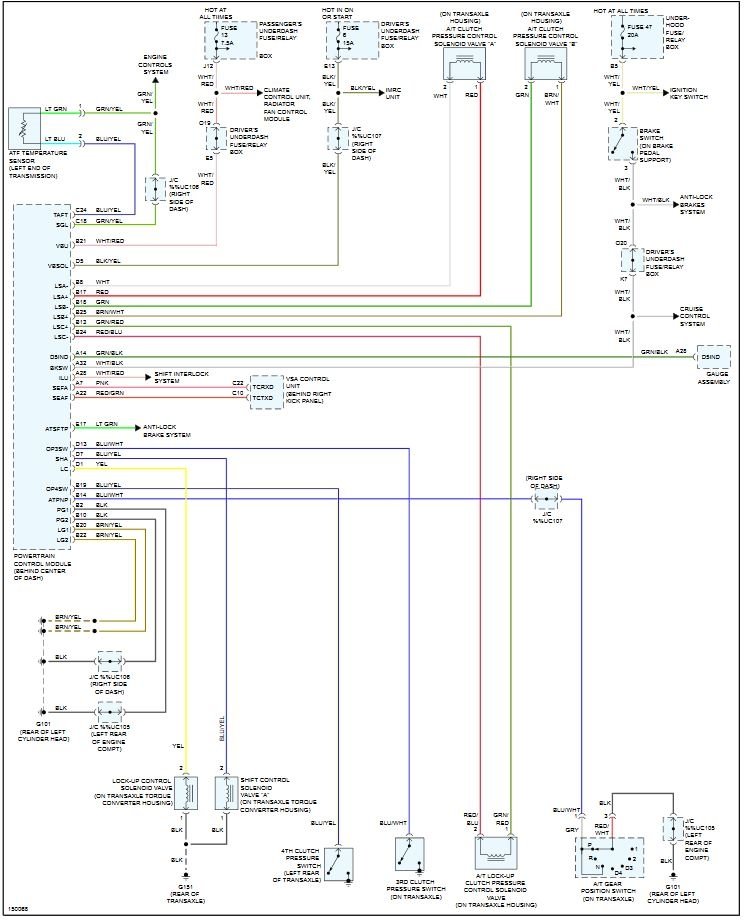

A failing clutch is more likely to slip in higher gears. In first or second gear, there is less of a load on it because of the gear ratio. If you were to place it in 4th or 5th and accelerate hard, does it slip? If it does, the clutch needs replaced. this video will walk you throught he job on a similar car the process is this same.

https://youtu.be/6N6b5F2ChyE

___________________________________

Let me know if that is what happens. Also, if you want to replace the clutch, here are the directions. Note the pics correlate with the directions.

___________________________________

2010 Acura TL AWD V6-3.7L

Removal and Replacement

Vehicle Transmission and Drivetrain Clutch Pressure Plate Service and Repair Removal and Replacement

REMOVAL AND REPLACEMENT

Clutch Replacement

Special Tools Required

- Clutch Alignment Disc 07JAF-PM7011A

- Ring Gear Holder 07LAB-PV00100

- Clutch Alignment Tool Set 07PAF-0020000

- Clutch Alignment Pilot, 20 mm 07PAF-0020360

- Clutch Alignment Shaft 07ZAF-PR8A100

- Attachment, 22 x 24 mm 07746-0010800

- Driver Handle, 15 x 135L 07749-0010000

- Remover Handle 07936-3710100

- Bearing Remover Shaft Set, 20 mm 07936-3710600

- Slide Hammer 07936-371020A

Engine Side

Pressure Plate Inspection and Removal

1. Remove the transmission See: Manual Transmission/Transaxle > Removal and Replacement > Manual Transmission Removal.

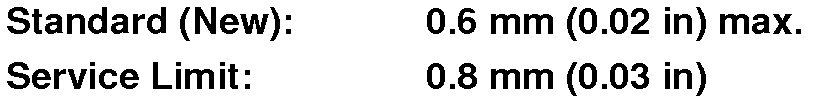

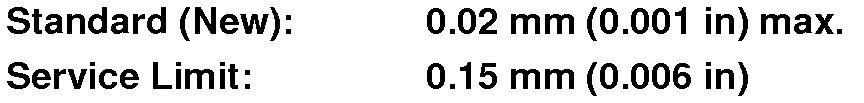

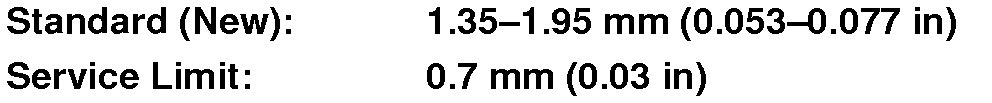

2. Check the evenness of the height of the diaphragm spring fingers using the clutch alignment disc (A), the clutch alignment shaft (B), the remover handle (C), and a feeler gauge (D). If the height difference is more than the service limit, replace the pressure plate.

pic 1

pic 2

3. Install the ring gear holder (A), the clutch alignment tool set (B), and the 20 mm clutch alignment pilot (C).

pic 3

4. To prevent warping, loosen the pressure plate mounting bolts (D) in a crisscross pattern in several steps, then remove the pressure plate (E).

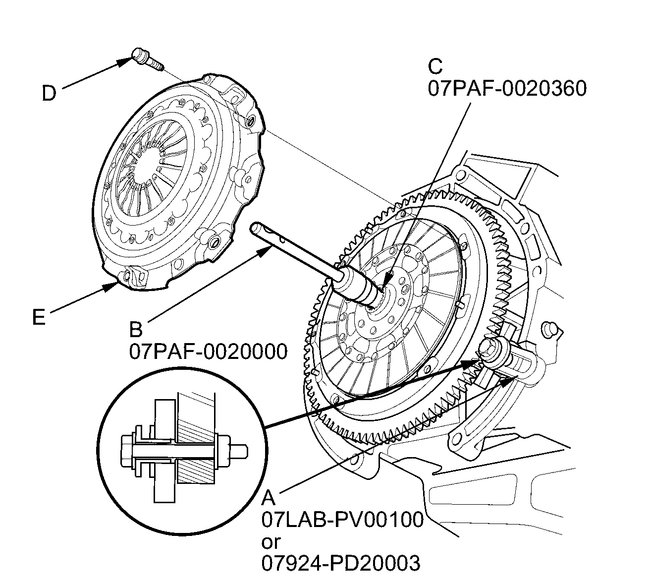

5. Inspect the fingers of the diaphragm spring (A) for wear at the release bearing contact area.

pic 4

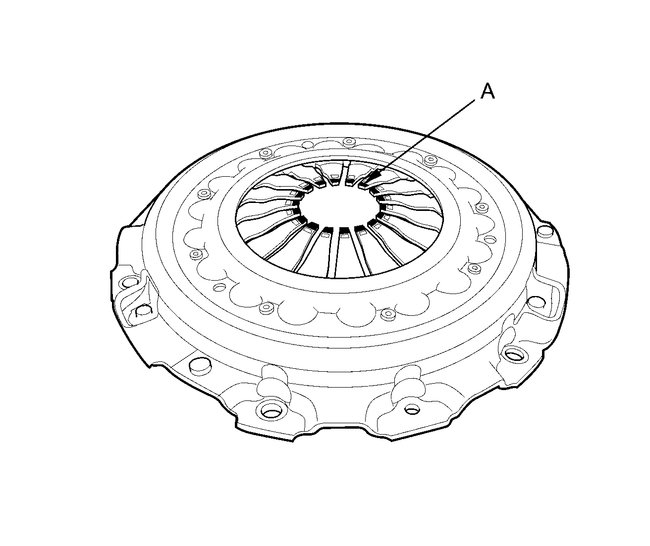

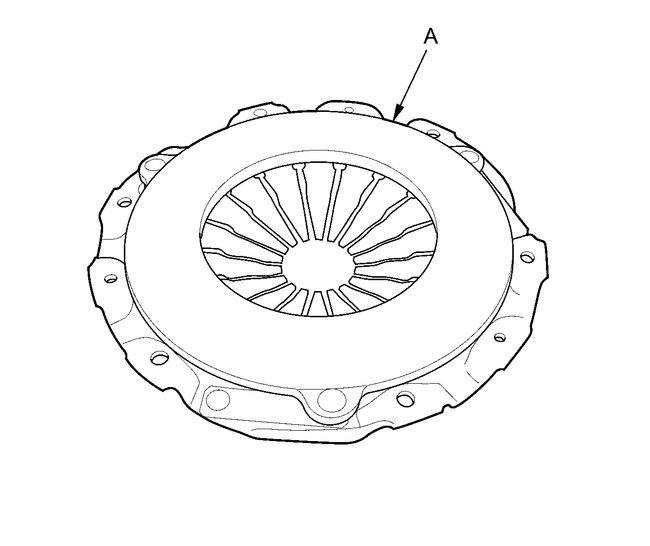

6. Inspect the pressure plate surface (A) for wear, cracks, and burning.

pic 5

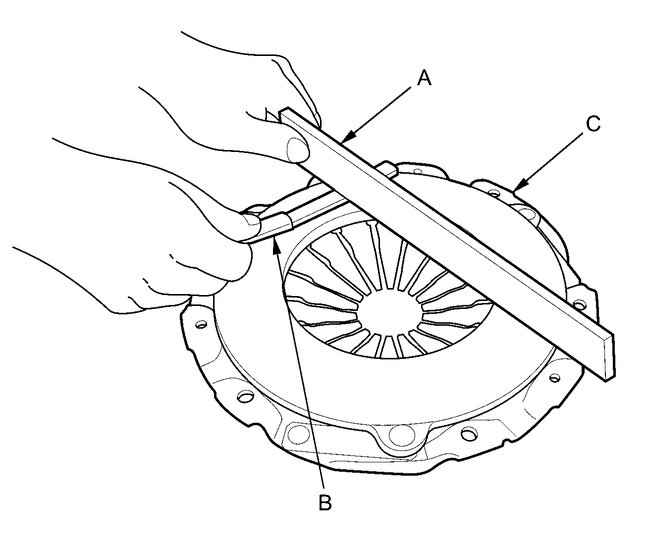

7. Inspect for warpage using a straight edge (A) and a feeler gauge (B). Measure across the pressure plate (C). If the most measurement difference is more than the service limit, replace the pressure plate.

pic 6

pic 7

Clutch Disc Inspection and Removal

8. Remove the clutch disc (A), the clutch alignment tool set (B), and the 20 mm clutch alignment pilot (C).

pic 8

9. Inspect the lining of the clutch disc for signs of slippage or oil. If the clutch disc looks burnt or is oil soaked, replace the clutch disc. If the clutch disc is oil soaked, find and repair the source of the oil leak.

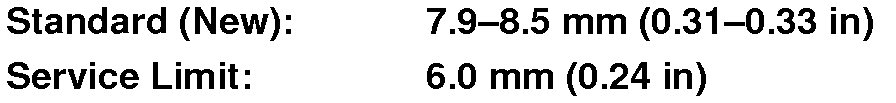

10. Measure the clutch disc thickness. If the measurement is less than the service limit, replace the clutch disc.

pic 9

pic 10

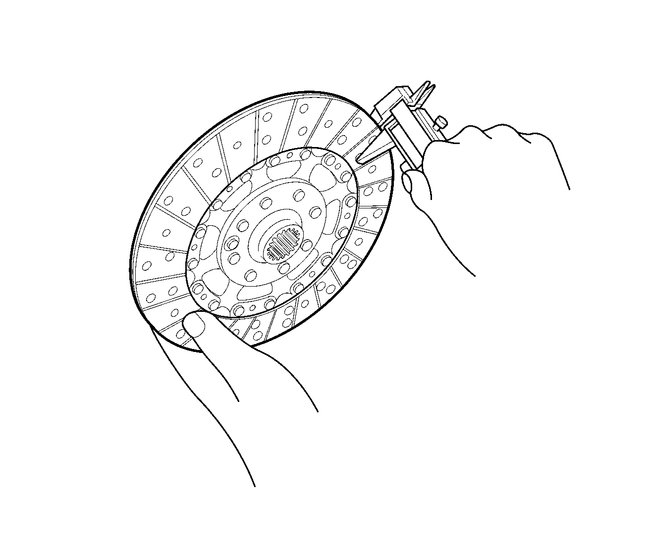

11. Measure the depths of the rivets from the clutch disc lining surface (A) to the rivets (B) on both sides. If the measurement is less than the service limit, replace the clutch disc.

pic 11

pic 12

Flywheel Inspection

12. Remove the ring gear holder.

13. Inspect the ring gear teeth for wear and damage.

14. Inspect the clutch disc mating surface on the flywheel for wear, cracks, and burning.

15. Measure the flywheel (A) runout using a dial indicator (B). Through at least two full turns with pushing against the flywheel each time you turn it to take up the crankshaft thrust washer clearance. If the measurement is not within the standard, replace the flywheel, and recheck the runout; go to step 16.

pic 13

pic 14

Flywheel Replacement

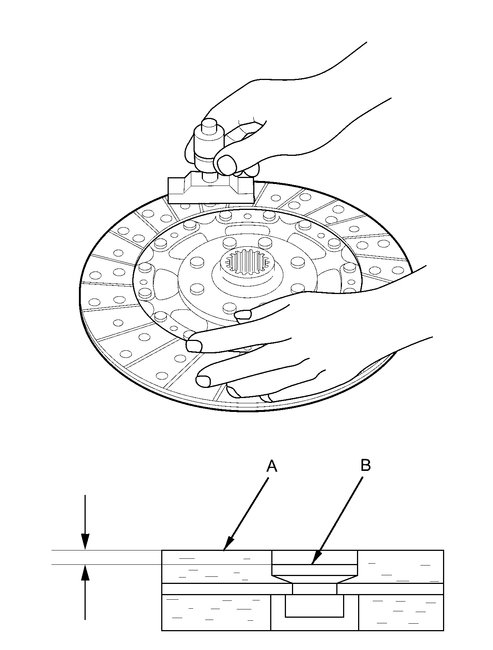

16. Install the ring gear holder (A).

pic 15

17. Loosen the flywheel mounting bolts in a crisscross pattern in several steps. Remove the bolts, then remove the flywheel and the ring gear holder.

18. Install the flywheel on the crankshaft, and install the mounting bolts finger-tight.

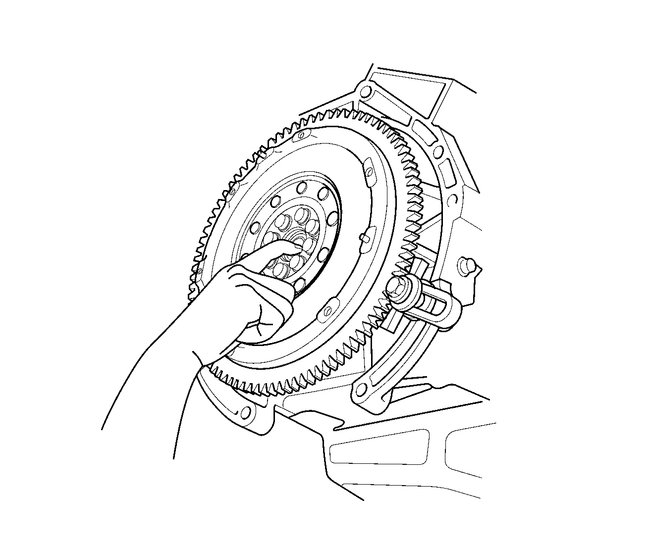

19. Install the ring gear holder (A), then torque the flywheel mounting bolts (B) in a crisscross pattern in several steps.

pic 16

Pilot Bearing Inspection

20. Turn the inner race of the pilot bearing with your finger. The pilot bearing should turn smoothly and quietly. Check that the pilot bearing outer race fits tightly in the flywheel. If the race does not turn smoothly, quietly, or fit tight in the flywheel, replace the pilot bearing; go to step 21.

pic 17

Pilot Bearing Replacement

21. Remove the pilot bearing (A) using the slide hammer (B), the remover handle (C), and the 20 mm bearing remover shaft set (D).

pic 18

22. Install a new pilot bearing (A) into the crankshaft using the 15 x 135L driver handle (B) and the 22 x 24 mm attachment (C).

pic 19

Clutch Disc and Pressure Plate Installation

23. Temporarily install the clutch disc onto the splines of the transmission mainshaft. Make sure the clutch disc slides freely on the mainshaft.

24. Apply super high temp urea grease (P/N 08798- 9002) to the splines (A) of the clutch disc (B), then install the clutch disc using the clutch alignment tool set (C) and the 20 mm clutch alignment pilot (D).

pic 20

25. Align (±60 degrees) the point marks (A) across the pressure plate (B) and the flywheel (C).

pic 21

26. Install the pressure plate and the mounting bolts (D), finger-tight.

27. Torque the mounting bolts (A) in a crisscross pattern. Tighten the bolts in several steps to prevent warping the diaphragm spring. Make sure that there is not clearance between the pressure plate and the flywheel.

pic 22

pic 23

28. Remove the ring gear holder (B), the clutch alignment tool set (C), and the 20 mm clutch alignment pilot.

29. Make sure the diaphragm spring fingers are all the same height.

30. Do the release bearing inspection, and replace it if necessary.

31. Install the transmission See: Manual Transmission/Transaxle > Removal and Replacement > Manual Transmission Installation.

Transmission Side

Release Bearing Removal

1. Remove the transmission See: Manual Transmission/Transaxle > Removal and Replacement > Manual Transmission Removal.

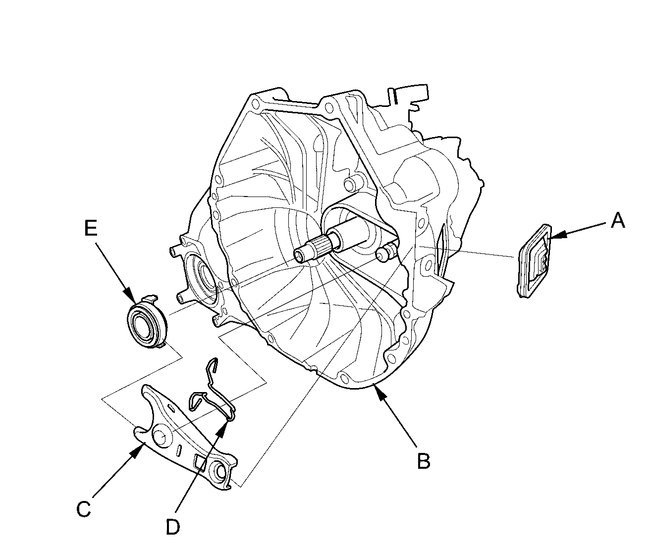

2. Remove the release fork boot (A) from the clutch housing (B).

pic 24

3. Remove the release fork (C) from the clutch housing by squeezing the release fork set spring (D). Remove the release bearing (E).

Release Bearing Inspection

4. Check the play of the release bearing by spinning it by hand. If there is excessive play or noise, replace the release bearing.

NOTE: The release bearing is packed with grease. Do not wash it in solvent.

pic 25

Release Bearing Installation

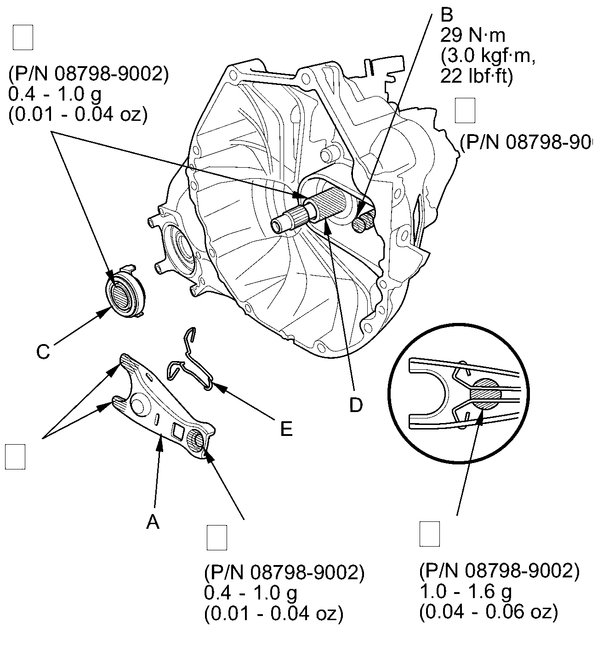

5. Apply super high temp urea grease (P/N 08798-9002) to the release fork (A), the release fork bolt (B), the release bearing (C), and the release bearing guide (D) in the shaded areas, then set the release fork set spring (E).

NOTE: Replace the release fork bolt if necessary.

pic 26

6. With the release fork (A) slide between the release bearing pawls (B), install the release bearing on the mainshaft while inserting the release fork through the hole (C) in the clutch housing.

pic 27

7. Align the detent (D) of the release fork with the release fork bolt (E), then press the detent of the release fork over the release fork bolt squarely.

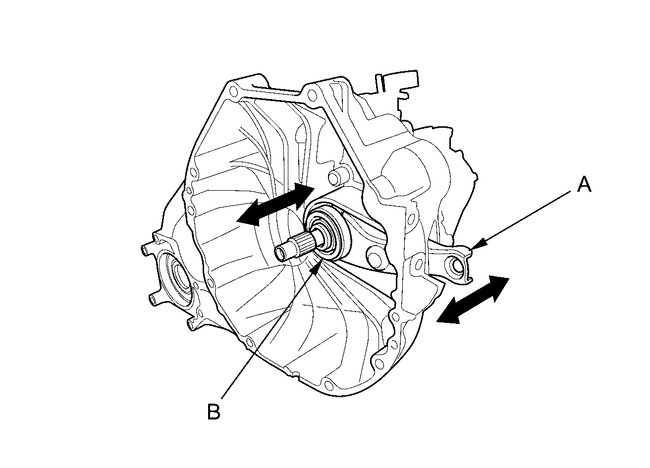

8. Install the release fork boot (F). Make sure the boot seals around the release fork and the clutch housing.

9. Move the release fork (A) right and left to make sure that it fits properly against the release bearing (B) and that the release bearing slides smoothly. Wipe off any excess grease.

pic 28

10. Install the transmission See: Manual Transmission/Transaxle > Removal and Replacement > Manual Transmission Installation.

________________________________________

I hope this helps. Let me know if you have other questions or need help.

Take care,

Joe

Images (Click to make bigger)

Thursday, January 28th, 2021 AT 4:45 PM