Wednesday, March 10th, 2021 AT 8:53 PM

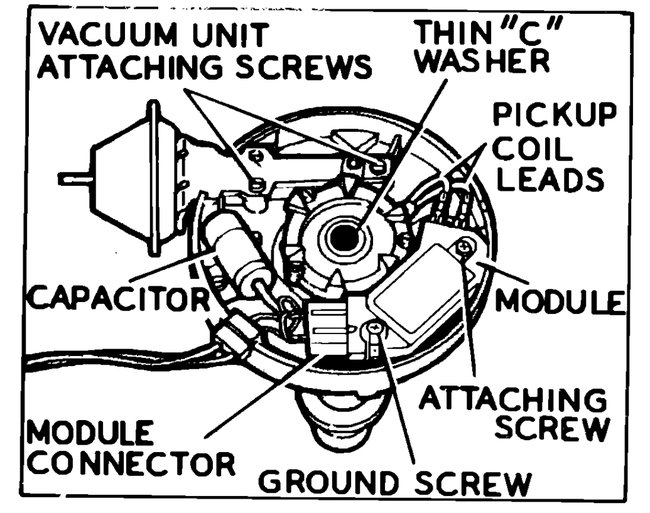

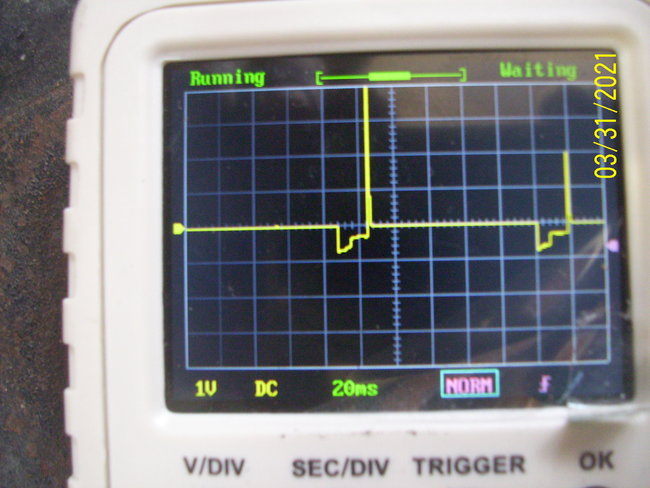

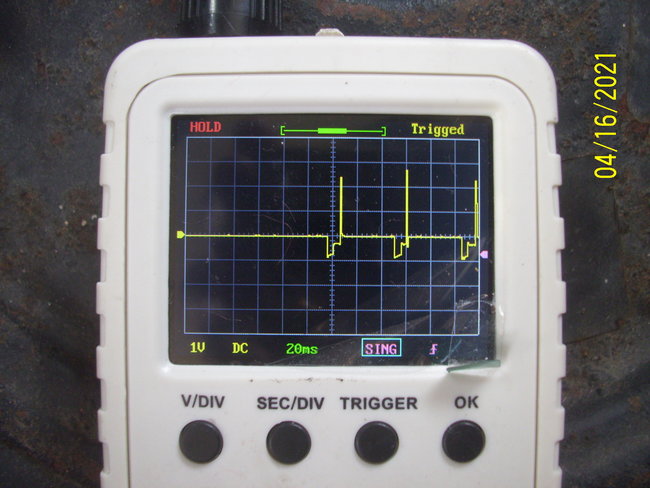

I have the vehicle listed above 454 HEI. About a year ago it wouldn't start. Via my ignorance, I checked for spark with a Harbor Freight spark light tester, it lit up indicating it had spark, still no start. After reading much I learned the correct tester is a HEI spark gap tester (which the ignition would not fire). I replaced the coil and HEI spark was restored and the engine ran fine. Unfortunately recently, I was rolling down the road, and the engine sputtered and shut off, not to start again. I replaced the coil while on the side of the road still no start. I have the same test results as above (weak spark on the coil output via a spark light tester, no spark via a spark gap tester), I have 12V on the battery input to distributor (which dips to ~10V while cranking), a trouble light placed between the battery and tachometer inputs to the distributor blinks as expected during cranking. All wires are connected to the coil (including the external ground from the ignition module). Since I've tested for HEI spark back to the secondary of the coil (and I don't have any), the only thing left that I can think of that would cause this is a ground failure. Any other suggestions?