Sunday, August 26th, 2018 AT 10:09 PM

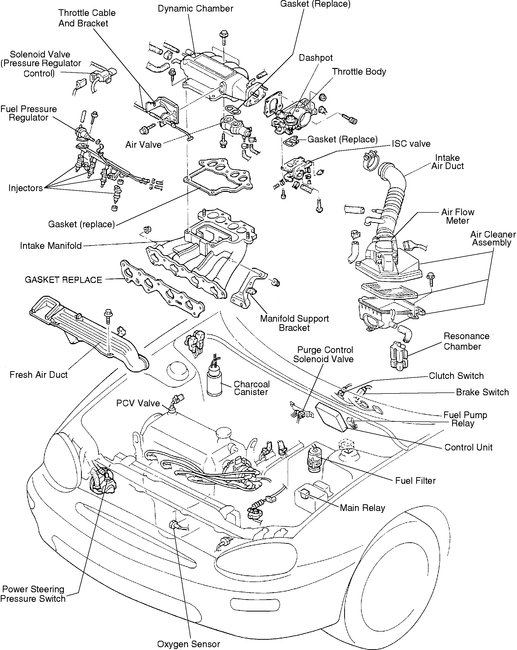

Car ran great until a week ago. It started missing, sputtering and became harder to start. No check engine light on during all this. It cuts out going up hills, but smooths out after cresting the hill. If I am on the highway on a hot day it starts to sputter and loose power around seventy mph. When I get off the highway it runs rough at idle, sputtering and coughing. If I shut it off it is near impossible to start again. Still no check engine light. If it is cold out it will crank over but no start, I usually park on an incline and it will start by popping the clutch but not by turning it over. Mechanic friend said change coolant sensor so I did. Now check engine light is on, took that sensor back got another, same thing. Check engine light is on and car runs really bad. Trouble code flashes 9, coolant sensor. I have changed all three coolant sensors, the one screwed into the head on front of motor, the fan sensor screwed into the thermostat housing and the on in the intake manifold. The plug was bad on the intake sensor so I replaced it also. The sensor in the intake was the one I replaced twice, check engine light went out when I changed the connector plug, motor still rough running. I removed the throttle body and cleaned the butterfly, put it back together and now the idle is up and down between 900 and 2,000 rpm's and motor is still sputtering. I disconnected the coolant sensor in the intake and the motor does not hesitate but still has high idle. I reconnect it and the motor falls on its face. I am at wits end, can you steer me in the right direction?