First you must be aware there are different quality brake pads. The least expensive linings are the most quiet because they are kind of soft. The higher-quality linings are harder and they do make a rubbing or grinding noise but that goes away when they get warm. Many new linings also have a relatively hard outer surface to help them seat on newly-machined rotors. Machining rotors leaves them with grooves just like on a record. Until those wear down, the linings will not make full contact and braking power will be greatly reduced. Experienced shop owners tell their employees to tell their customers to leave extra stopping distance and time for the first few hundred miles after any brake work has been done. Also, if you weren't told this already, you should ignore new noises after a brake job for the first few hundred miles. Experienced brake specialists recognize the sounds of new linings, and they know they aren't going to be able to quiet them. They know what is going to go away on its own, and they know what is not normal and needs to be corrected. Unfortunately, in the first case, most mechanics don't do a good job of communicating that information. The people at some shops just tell you to not come back for at least two weeks. They know most of the noises go away and the owners don't come back, but they forget that those people left in a fowl mood. That mood will be remembered long after the noises are forgotten.

Regardless of the type of linings used, you also have to look at the surface finish on the rotors. Even new rotors have grooves in them. If they were perfectly smooth, that still wont match the rough surface of the new linings. Every mechanic is familiar with what happens when the rotors are too smooth, or when the old ones aren't machined during a brake job. Because the linings are rough at first, there's that reduced surface contact, and to get the needed stopping power you have to push harder on the brake pedal. That results in increased heat buildup, and the binders in the linings melt and cause glazing. That leads to one form of brake fade. On one of my brake jobs no one told the owner to take it easy for week, and with a lot of aggressive driving habits, she overheated the linings and had no braking power left at all. All that was needed was to let the brakes cool down for half an hour and she had no more problems. The grooves on the rotor surfaces help to grind off that glazing and they help the new linings wear smooth and make full contact, but that takes a few hundred miles to occur. If you're hearing a rough grinding or rubbing noise when you apply the brakes, don't panic over that yet. Give the linings a few hundred miles to seat, then see if you still hear the noise.

If you're hearing a crunching noise, especially when cornering, the mechanic failed to use a high-temperature brake grease between the rotor and hub. That doesn't hurt anything but it can be pretty irritating. That applies more to front wheels on older GM front-wheel-drive cars but it can happen on other models. The clue is the noise occurs on corners whether you're braking or not.

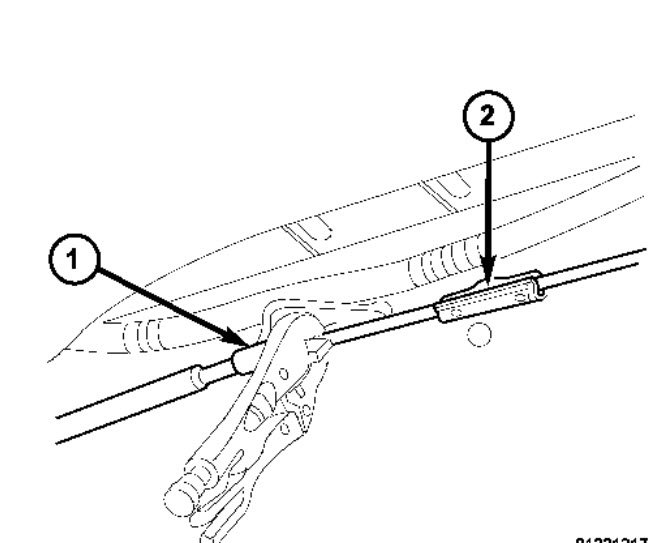

There are a real lot of other noises mechanics can inadvertently cause, and can fail to prevent when they do a brake job. It doesn't pay to describe all of them here because they don't match what you described. If the noise doesn't go away, there is a tool called the "Chassis Ear" that can be useful. It is a set of six microphones, a switch box, and headphones. You clip the microphones to suspect points, then drive around while listening with the headphones. You can move the microphones around to zero in on the source of the noise. Be aware that many mechanics have never seen or even heard of this tool. Suspension and alignment mechanics use it to find rattles, squeaks, and other noises. That was my specialty at a very nice Chrysler dealership in the '90s. The tool was issued to each dealership but it got very little use by most of the mechanics.

Tuesday, September 10th, 2019 AT 5:17 PM

(Merged)