CAMSHAFT

Removal

Remove cam cover(s). See CAM COVER(S) . Secure cam sprocket to timing chain using tie wraps through cam sprocket holes (2 tie wraps per sprocket).

CAUTION:Sprocket/chain relationship must be maintained throughout this procedure or camshaft timing will be lost and require further engine disassembly to retime.

Working behind sprockets, install Cam Chain Holder (J 38815) so it is positioned between chain tensioner and chain guide. See Fig. 8 . Apply tension to holder by tightening tension adjusting screw.

Fig. 8: Installing Cam Chain Holder

Courtesy of GENERAL MOTORS CORP.

Remove both cam sprocket bolts. (Note and mark location of cam drive pins in end of camshafts). Work sprockets off cams using play in chain.

Alternately loosen cam bearing cap screws a few turns at a time until all valve spring pressure has been released. Remove bolts and caps. Remove camshafts.

Inspection

Whenever a camshaft is removed the lobes should be visually checked. Excessive wear, scoring or flaking of the lifter will usually denote camshaft lobe wear. Excessive camshaft lobe wear is evidenced by grooves, scoring or flaking. Camshaft should be replace if any of these conditions exist. Bearing journals should not be scored or burned.

Installation

Apply prelube (1052365) to face of each cam lobe. Position camshaft and bearing caps on head. Loosely install bearing cap bolts.

NOTE:Each cap is identified for position and direction. Arrow points to front of engine. "E" indicates exhaust cam. "I" indicates intake cam. Position No. 1 is toward front of engine.

Alternately tighten bearing cap bolts a few turns at a time until all bolts are snug. Tighten bolts to specification. See TORQUE SPECIFICATIONS .

Use hex cast into camshaft to adjust cams until drive pins are in position to engage cam sprockets over cams and then start retaining bolts. Work sprockets over cams and tighten retaining bolts to specification. To finish installation, reverse removal procedure.

Fig. 9: Adjusting Cam Position

Courtesy of GENERAL MOTORS CORP.

NOTE:Setting camshaft timing is necessary whenever cam drive system has been disturbed such that the relationship between any chain and sprocket has been lost. Even when only one sprocket is involved the timing procedure should be observed since one crankshaft revolution will not confirm correct timing.

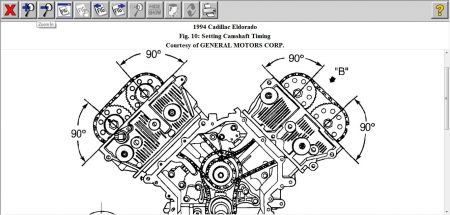

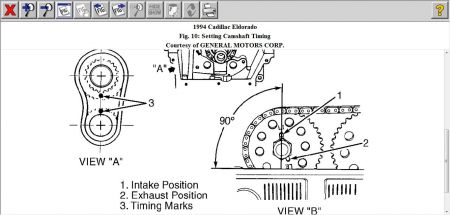

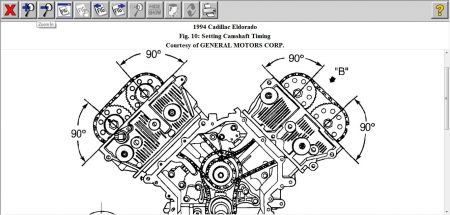

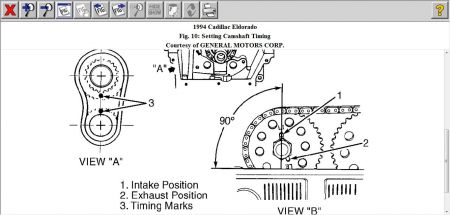

NOTE:The camshafts and crankshaft are correctly timed when the relationships shown in Fig. Fig. 10 exist. Correct timing exists when crank sprocket and intermediate shaft sprocket have their timing marks aligned and all 4 camshaft drive pins are perpendicular to cylinder head surface. See Fig. 10 .

Camshaft Timing

Remove cam covers. See CAM COVER(S) . Remove front cover. See FRONT COVER . Remove or fully retract all 3 chain tensioners. Remove oil pump. See OIL PUMP under ENGINE OILING.

Primary and secondary chain guides should remain in place. Rotate crankshaft until sprocket drive key is positioned at about 1 o'clock.

Set crankshaft and intermediate shaft sprockets into primary drive chain with their timing marks adjacent to each other. See Fig. 10 .

Install crank and intermediate sprockets over their respective shafts. Rotate crankshaft as necessary to engage crankshaft key in sprocket without changing the timing mark relationship.

Install Flywheel Holder (J 39411) to lock crankshaft in position. (If engine is on stand, an alternate locking method should be devised. Install intermediate sprocket retaining bolt and tighten to specification. See TORQUE SPECIFICATIONS .

Route secondary chain for left hand cylinder head over inner row of intermediate shaft teeth. Route secondary drive chain over chain guide and install exhaust cam sprocket to chain so that camshaft drive pin engages sprocket notch marked LE (left head exhaust). There should be no slack in lower section of chain and cam drive pin must be perpendicular to cylinder head face. See Fig. 10 .

Fig. 10: Setting Camshaft Timing

Courtesy of GENERAL MOTORS CORP.

Install intake cam sprocket into chain so the sprocket notch marked LI (left head intake) engages cam drive pin while pin remains perpendicular to head face. Minor cam positioning adjustments can be made using open end wrench on hex cast into camshaft.

Install sprocket retainer bolts and chain tensioner and tighten to specification. See TORQUE SPECIFICATIONS .

Route secondary chain for right hand cylinder head over outer row of intermediate shaft teeth and repeat steps No. 6) 8). Right hand cam sprockets are identified RI (right intake) and RE (right exhaust). In addition, RE sprocket must contain cam position sensor pickup.

SPONSORED LINKS

Wednesday, October 27th, 2010 AT 8:00 AM