Hello.

I did also find this TSB that may be of interest to you ..!!

"ANTILOCK"/"TRACTION OFF" LIGHT STAYS ON - CODE 61

TECHNICAL SERVICE BULLETIN

Reference Number(s): 53-50-17

Related Ref Number(s): 53-50-17

ARTICLE BEGINNING

AMBER ANTILOCK WARNING LIGHT AND (IF EQUIPPED) AMBER TRACTION OFF WARNING LIGHT STAYS ON (APPLY SEALANT/GREASE)

Model(s): 1995 Buick LeSabre, Park Avenue; 1995 Oldsmobile Ninety Eight, Eighty Eight; 1995 Pontiac Bonneville

Bulletin No.: 5 - Brakes

Section: 53-50-17

Date: February, 1996

MODELS AFFECTED

1995 Pontiac Bonneville Built Prior to June 1, 1995.

CONDITION

Some owners may comment that the amber antilock warning light and (if equipped) amber traction off warning light stays on. Also, the antilock brake system and (if equipped) traction control system may become inoperative. The following conditions will occur:

Amber antilock warning light and (if equipped) amber traction off warning light turns on and stays on. The red brake warning light stays off.

EBTCM Diagnostic Trouble Code (DTC) 61 will be set.

NOTE:THIS CONDITION IN NO WAY AFFECTS THE OPERATION OF THE POWER BRAKES.

CAUSE

Fluids trapped in the wire harness in the area below the windshield washer reservoir. This allows the fluids to come in contact with the ground splice for the Pressure Modulator Valve (PMV) motor (S129) and to be wicked down CKT 1150 to the 4-way brake PMV connector C2. Sufficient fluids in the connector interfere with the pump run signal, causing a DTC 61 to set. This condition DOES NOT damage the Electronic Brake Traction Control Module (EBTCM).

CORRECTION

Seal splice S129 with electrical moisture sealant, P/N 11515174. Cut sealant into approximately a 2" x 2" square. Position seam in flexible conduit down or slit the bottom of the conduit in area of splice S129 and apply electrical connector grease, P/N 12377900, to terminals in connector C2.

PROCEDURE

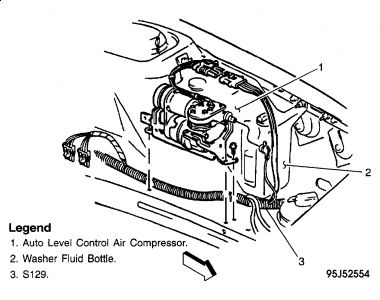

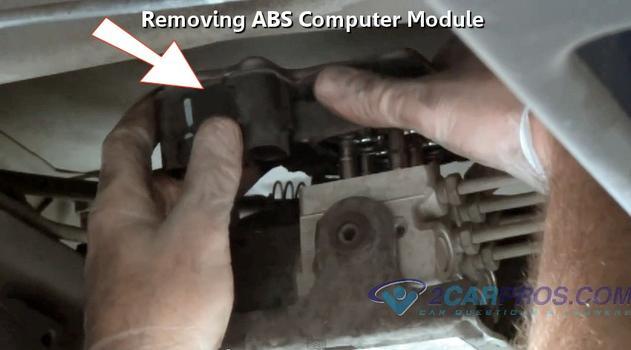

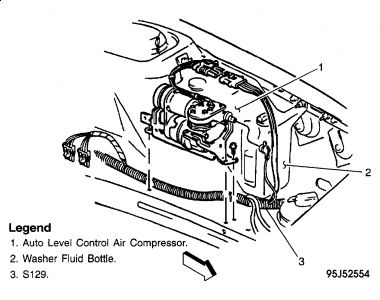

Remove air cleaner and windshield washer reservoir. For 3800 super charged engines, if equipped, remove the auto level control air compressor.

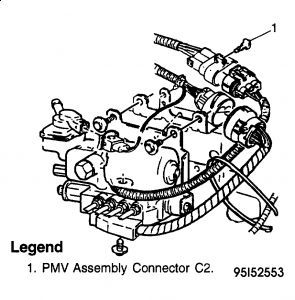

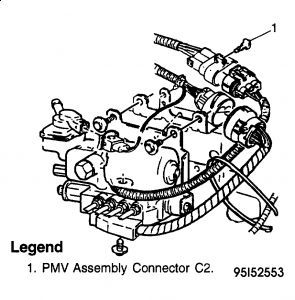

Remove flexible conduit covering the main harness 6 inches in both directions from the point where the wires break out to the PMV motor connector C2. See Fig. 1 .

Locate splice S129 and remove the tape covering it. See Fig. 2 . It is located about 2 inches forward from the point where the wires break out of the wiring harness for the connector C2.

Open connector C2.

CAUTION:TO PREVENT PERSONAL INJURY, WEAR HEARING AND EYE PROTECTION FOR THE NEXT STEP.

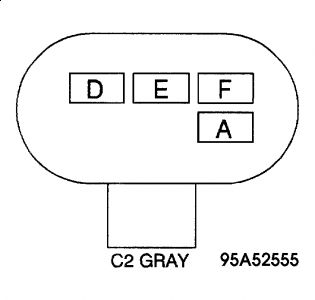

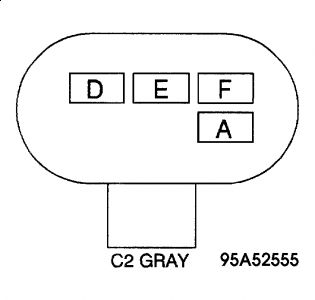

Using compressed air and a blow gun, blow air down terminal E on the harness side of connector C2 until no fluid can be seen being expelled from the wire at S129. See Fig. 3 . This will take several minutes.

Thoroughly dry splice S129 and the wires 2 inches in both directions.

Thoroughly clean the wires 2 inches in both directions of splice S129 with an alcohol wipe (available locally) and allow to completely dry.

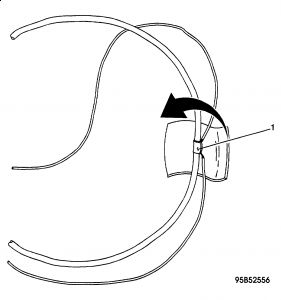

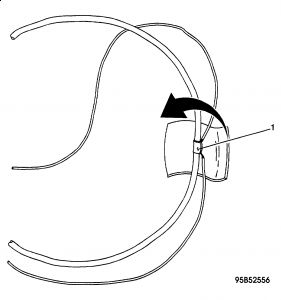

Cut a 2" x 2" piece of electrical moisture sealant. Apply the moisture sealant patch to the splice by folding it over the wires. Make sure that there is at least a 1/8 inch gap between any parallel wires to ensure that the patch can seal between the wires. See Fig. 4 . Press the patch together with your fingers or duck bill pliers, making sure that the wires are completely sealed.

Return the harness to its original condition, making sure that the conduit seam in the area of the splice is on the bottom of the harness or slit the bottom of the conduit and make sure that any tape used to secure the conduit will allow any trapped fluids to drain.

Using a brush such as an acid brush (available locally), thoroughly coat both the male and female terminals of connector C2 with the electrical connector grease.

Reconnect connector C2 and reassemble the washer fluid reservoir, air cleaner and, if necessary, the electronic level control pump.

Hope this helps .. let me know

Monday, March 23rd, 2009 AT 12:46 PM