Here's how to check it all out.

SUSPENSION - REAR ELECTRONIC LEVEL CONTROL -1997 Buick LeSabre Limited

Page 1 of 1

BASIC SYSTEM OPERATIONAL TEST

ELC System Check

1.Ensure height sensor and link assembly are in good condition before performing system operation test. Place vehicle on flat surface. Measure distance from ground to rocker panel in front of rear wheelwell opening. See Fig. 2 . 2.Turn ignition on. Add 300-350 lbs. (136-159 kg) of weight to rear of vehicle. After 17-27 second delay, compressor should turn on and vehicle should start to rise. Vehicle should rise to within 3/4" (19 mm) of measurement made in step 1). 3.Remove load from vehicle. After 17-27 second delay, vehicle should start to lower. Within 3 1/2 minutes, exhaust should stop and vehicle should be within 3/4" (19 mm) of measurement made in step 1). If ELC system does not function as specified, perform appropriate test. See ELC SYSTEM SYMPTOM TABLE .

CAUTION:System leak test determines if a leak exists, and if leak is internal or external to compressor.

Residual Air Pressure Test

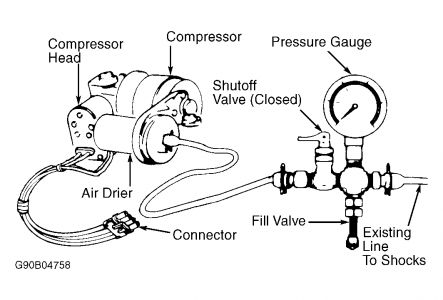

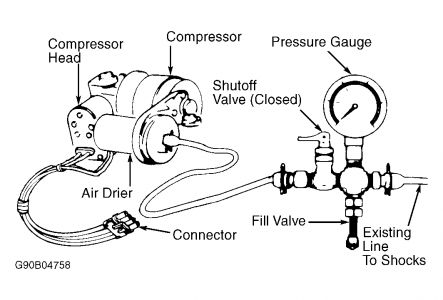

1.Install Pressure Gauge (J-22124-B ) and Adapter (J-22124-91 ) to air dryer and shock absorber. See Fig. 3 . Open shutoff/toggle valve. 2.Disconnect link from height sensor and move sensor arm up. Air compressor should operate, inflating one shock absorber. Move sensor arm down. Air compressor should stop and air should escape. Allow vehicle to go down as far as possible. 3.Connect link to height sensor. Read pressure gauge. If pressure gauge reads less than 7 psi (.5 kg/cm2 ), replace air dryer. Reconnect all air lines and check for leaks.

Fig. 3: Checking System For Leakage

Courtesy of GENERAL MOTORS CORP.

SUSPENSION - REAR ELECTRONIC LEVEL CONTROL -1997 Buick LeSabre Limited

Page 1 of 1

TEST 2: REAR OF VEHICLE HIGH

1.Check height sensor adjustment. SeeHEIGHT SENSOR under ADJUSTMENTS. If height sensor have been adjusted, go to step 3). If height sensor needs to be adjusted, go to next step. 2.Adjust height sensor. SeeHEIGHT SENSOR under ADJUSTMENTS. If problem is not corrected, go to next step. 3.Raise vehicle. Vehicle must be raised on a drive-on hoist or supported under rear axle. Full vehicle weight must be on rear suspension. Disconnect air line from air dryer. If air vents from line, go to step 5). If air does not vent from line, go to next step. 4.Check for binding in shock absorber. Replace as necessary. If shock absorber is okay, replace air line. After repairs, perform ELC SYSTEM CHECK see under BASIC SYSTEM OPERATIONAL TEST . 5.Reconnect air line to air dryer. Disconnect link from height sensor. Raise height sensor lever. If air compressor operates, go to step 7). If air compressor does not operate, go to next step. 6.Check ELC fuse or circuit breaker. Replace as necessary. If fuse or circuit breaker is okay, check for open in circuit between fuse or circuit breaker to height sensor. See WIRING DIAGRAM . After repairs, perform ELC SYSTEM CHECK see under BASIC SYSTEM OPERATIONAL TEST . If circuit is okay, go to TEST 3 . 7.Raise rear of vehicle as much as possible by holding height sensor arm up. Reconnect height sensor link. Disconnect air compressor harness connector. Check voltage at air compressor harness connector terminal "A" and ground. If battery voltage is present, go to step 9). If battery voltage is not present, go to next step. 8.Check for poor connection at power distribution center connectors C1 and C2 and relay center connector C4. If connections are okay, repair open in circuit between power distribution center and relay center. See WIRING DIAGRAM . After repairs, perform ELC SYSTEM CHECK see under BASIC SYSTEM OPERATIONAL TEST . 9.Cycle ignition switch. Check voltage between air compressor harness connector terminals "A" and "C". If battery voltage is present after 17-27 seconds (height sensor delay) after ignition was turned on, go to step 11). If battery voltage is still not present after 7 minutes, go to next step. 10.Check for open in circuit between air compressor and height sensor. See WIRING DIAGRAM . Check for poor connection at power distribution center connectors C1 and C2. Repair as necessary. After repairs, perform ELC SYSTEM CHECK see under BASIC SYSTEM OPERATIONAL TEST . If circuit and connections are okay, go to TEST 3 . 11.Replace air compressor head. After replacing compressor head, perform ELC SYSTEM CHECK see under BASIC SYSTEM OPERATIONAL TEST .

SUSPENSION - REAR ELECTRONIC LEVEL CONTROL -1997 Buick LeSabre Limited

Page 1 of 1

TEST 3: HEIGHT SENSOR TEST

1.Disconnect ELC height sensor connector. Turn ignition on, with engine off. Check voltage between ground and ELC height sensor harness connector terminal "C". If battery voltage is present, go to step 3). If battery voltage is not present, go to next step. 2.Repair open in circuit (Orange wire) between power distribution and air compressor. See WIRING DIAGRAM . After repairs, perform ELC SYSTEM CHECK see under BASIC SYSTEM OPERATIONAL TEST .

3.Check voltage between ELC height sensor terminals "A" and "C". If battery voltage is present, go to step 5). If battery voltage is not present, go to next step. 4.Repair open in circuit (Black wire) between air compressor and ground. After repairs, perform ELC SYSTEM CHECK see under BASIC SYSTEM OPERATIONAL TEST . 5.Check voltage between ELC height sensor harness connector terminals "A" and "D". If battery voltage is present, go to step 7). If battery voltage is not present, go to next step. 6.Repair open in circuit (Brown wire) between height sensor and power distribution center. After repairs, perform ELC SYSTEM CHECK see under BASIC SYSTEM OPERATIONAL TEST . 7.Check ELC height sensor harness connector contact. Repair as necessary. If terminal contact is okay, cycle ignition switch again and return to ON position. If air compressor operates for 3-5 seconds after a 35-55 second delay, go to step 9). If air compressor does not operate, go to next step. 8.Replace ELC height sensor. After replacing height sensor, perform ELC SYSTEM CHECK see under BASIC SYSTEM OPERATIONAL TEST . 9.Raise vehicle. Ensure rear wheels are supported as close as possible to trim height dimension. Disconnect link from ELC height sensor. Move height sensor arm upward. If air compressor operates after a 17-27 second delay, go to step 11). If not, go to next step. 10.Replace ELC height sensor. After replacing height sensor, perform ELC SYSTEM CHECK see under BASIC SYSTEM OPERATIONAL TEST . 11.Move height sensor arm down slightly until air compressor stops. If compressor stops, go to step 13). If compressor does not stop, go to next step. 12.Replace ELC height sensor. After replacing height sensor, perform ELC SYSTEM CHECK see under BASIC SYSTEM OPERATIONAL TEST . 13.Move height sensor arm downward. If air escapes from air compressor after a 17-27 delay (vehicle begins to lower), go step 15). If not, go to next step. 14.Replace ELC height sensor. After replacing height sensor, perform ELC SYSTEM CHECK see under BASIC SYSTEM OPERATIONAL TEST . 15.Adjust ELC height sensor. See HEIGHT SENSOR under ADJUSTMENTS. After adjustments, perform ELC SYSTEM CHECK see under BASIC SYSTEM OPERATIONAL TEST .

Friday, September 26th, 2008 AT 3:37 PM