Hi,

Was there an issue with the brake sticking on that wheel prior to replacement of the parts?

If there was, then suspect the rubber brake hose that connects to the rear of the caliper. Here is how to check. Safely lift that wheel off the ground and turn it by hand. If it turns, have a helper press and release the brake pedal. Does the brake actuate and then release? If it does actuate and not release, open the bleeder on the rear of the caliper to see if that releases the brake. If it does, replace the rubber brake hose.

If it doesn't release we have one of two issues. One is the caliper you purchases is sticking. The other is something is put together wrong.

Here are two links that explain how the job is done. Review them to see if you may have missed something.

https://www.2carpros.com/articles/how-to-replace-rear-brake-pads-and-rotors

https://www.2carpros.com/articles/brake-caliper-replacement

Here are directions specific to your vehicle for replacement of the brakes. See if anything was missed.

____________________________

2006 Dodge Stratus Sedan V6-2.7L VIN R

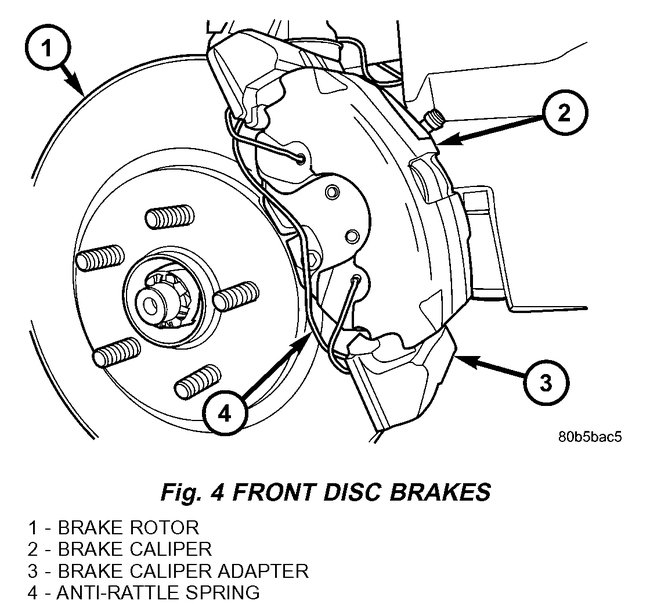

Front

Vehicle Brakes and Traction Control Disc Brake System Brake Pad Service and Repair Procedures Removal and Installation Front

FRONT

BRAKE PADS/SHOES FRONT

REMOVAL

1. Raise the vehicle. .

2. Remove both front wheel and tire assemblies.

NOTE: Using this procedure, begin on one side of the vehicle.

pic 1

3. Remove the anti-rattle spring from the outboard side of the caliper and adapter (Fig. 4).

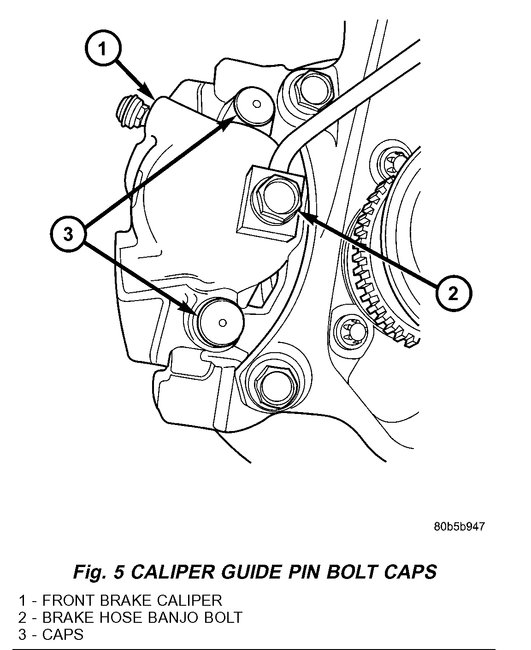

pic 2

4. Remove the two caps in place over the caliper guide pin bolts (Fig. 5).

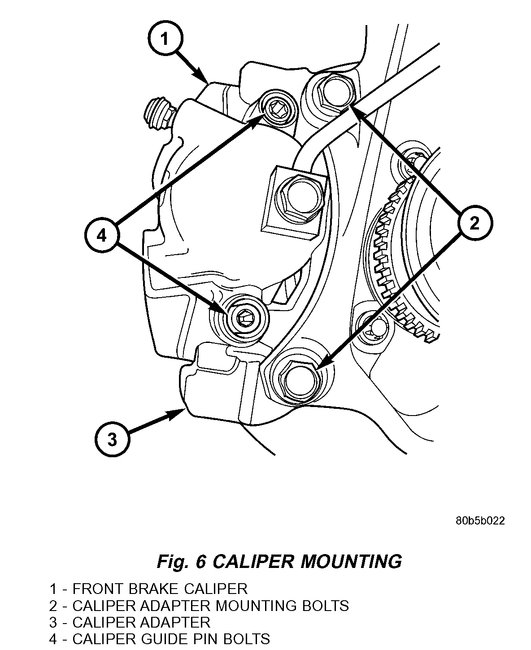

pic 3

5. Remove the two caliper guide pin bolts (Fig. 6).

6. Remove caliper from caliper adapter and brake rotor. The outboard shoe will probably stay with the caliper adapter while the inboard shoe will come off with the caliper as the caliper is removed.

CAUTION: Supporting weight of caliper by the flexible brake fluid hose can damage the hose.

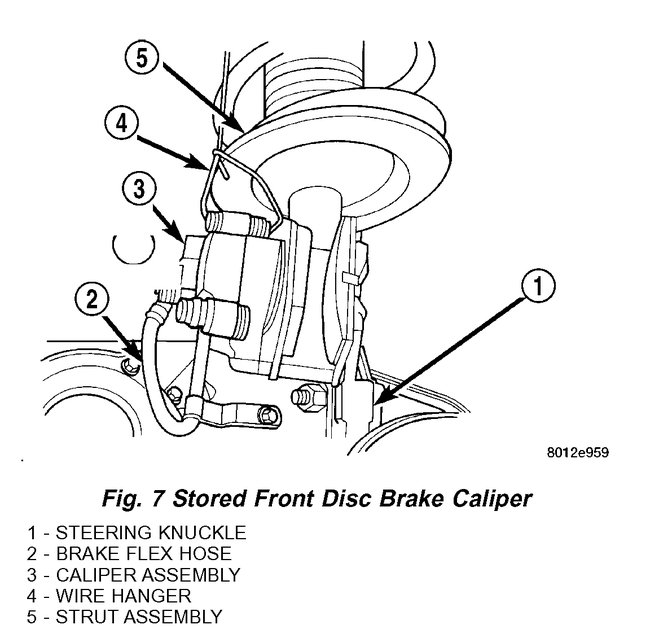

pic 4

7. Using wire or cord, hang the caliper from the front strut assembly (Fig. 7). Support the caliper firmly to prevent weight of caliper from being supported by the brake fluid hose.

8. Remove the outboard brake shoe from the caliper adapter.

pic 5

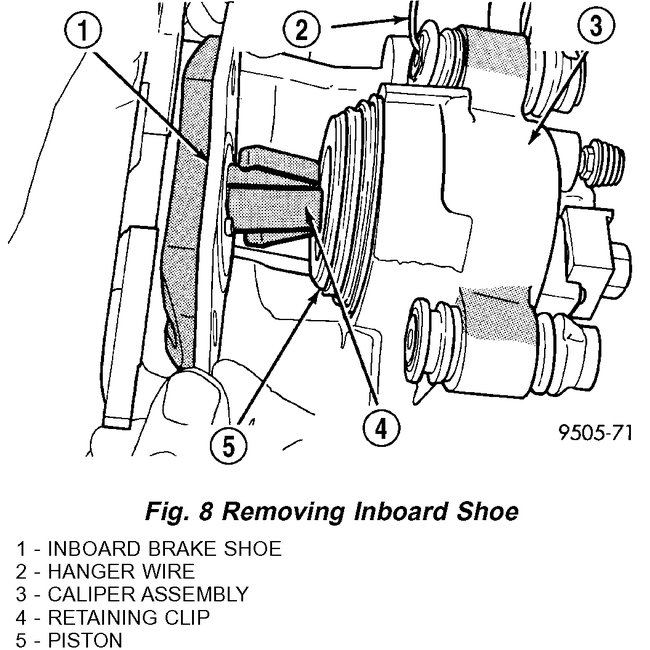

9. Pull the inboard brake shoe away from the caliper piston until the retaining clip on shoe is free from the cavity in the caliper piston (Fig. 8).

10. Repeat the above procedure on other side of the vehicle.

Cleaning - disc brake shoes

warning: dust and dirt accumulating on brake parts during normal use may contain asbestos fibers from production or aftermarket brake linings. Breathing excessive concentrations of asbestos fibers can cause serious bodily harm. Exercise care when servicing brake parts. Do not sand or grind brake lining unless equipment used is designed to contain the dust residue. Do not clean brake parts with compressed air or by dry brushing. Cleaning should be done by dampening the brake components with a fine mist of water, then wiping the brake components clean with a dampened cloth. Dispose of cloth and all residue containing asbestos fibers in an impermeable container with the appropriate label. Follow practices prescribed by the occupational safety and health administration (osha) and the environmental protection agency (epa) for the handling, processing, and disposing of dust or debris that may contain asbestos fibers.

INSPECTION

Visually inspect brake shoes (pads) for uneven lining wear. Also inspect for excessive lining deterioration. Check the clearance between the tips of the wear indicators on the shoes (if equipped) and the brake rotors.

If a visual inspection does not adequately determine the condition of the lining, a physical check will be necessary. To check the amount of lining wear, remove the disc brake shoes from the calipers.

Measure each brake shoe. The combined brake shoe and its lining material thickness should be measured at its thinnest point.

For front disc brake shoes, when a set of brake shoes are worn to a thickness of approximately 7.0 mm (9/32 inch), they should be replaced.

For rear disc brake shoes, when a set of brake shoes are worn to a thickness of approximately 7.0 mm (9/32 inch), they should be replaced.

Typically, if front shoes are worn out, both fronts and rears need to be replaced. Make sure to check rears.

Replace both disc brake shoes (inboard and outboard) on each caliper. It is necessary to replace the shoes on the opposite side of the vehicle as well as the shoes failing inspection.

If the brake shoe assemblies do not require replacement, be sure to reinstall the brake shoes in the original position they were remove from.

INSTALLATION

NOTE: There may be more than 1 lining material released. Make sure proper linings are being installed.

1. Begin on one side of the vehicle or the other.

2. Completely retract the caliper piston back into its bore in the brake caliper (This is required for caliper installation on the brake rotor with new brake shoes installed).

3. If applied, remove the protective paper from the noise suppression gasket on the rear of both the inner and outer brake shoe assemblies.

pic 6

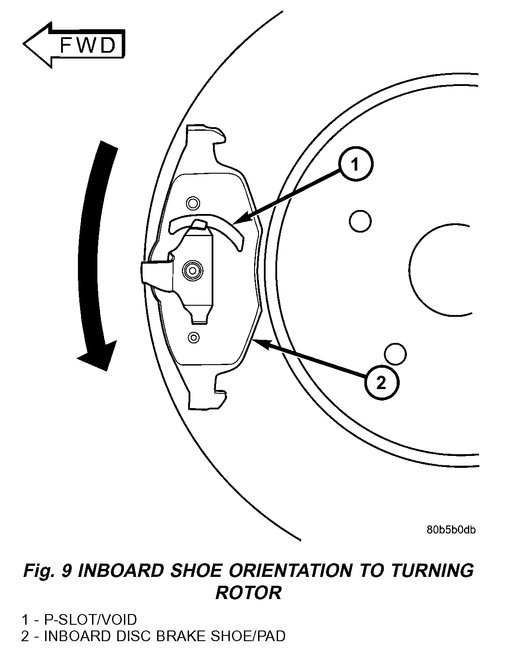

NOTE: Inboard brake shoes are stamped L or R for left or right side of the vehicle. The P-slot or void on piston insulator must be positioned upward when brake caliper is mounted (Fig. 9).

4. Install the new inboard brake shoe into the caliper piston by firmly pressing its retaining clip into the piston bore. Be sure the inboard brake shoe is positioned squarely against the face of the caliper piston.

5. Lubricate both adapter abutments where the shoes slide with a small amount of Mopers Dielectric grease, or equivalent.

6. Slide the new outboard brake shoe into the caliper adapter with the lining up against the outside of the brake rotor.

CAUTION: Use care when installing the caliper assembly onto the caliper adapter, so the caliper guide pin bushings do not get damaged by the adapter bosses.

7. Carefully position the brake caliper over the brake rotor and adapter.

8. Install the caliper guide pin bolts and tighten to a torque of 35 Nm (26 ft. lbs.). Extreme caution should be taken not to cross thread the caliper guide pin bolts.

9. Install the caps over the caliper guide pin bolts (Fig. 5).

10. Install the new caliper hold down spring (antirattle clip) on the outboard side of the caliper. Start the spring into the holes on the caliper, then stretch the clip legs past the abutments on the caliper adapter (Fig. 4).

11. Repeat the above procedure on other side of the vehicle.

12. Install the wheel and tire assemblies. Tighten the wheel mounting nuts in proper sequence until all nuts are torqued to half specification, then repeat the tightening sequence to the full specified torque of 135 Nm (100 ft. lbs.).

13. Lower vehicle.

14. Pump the brake pedal several times. This will set the shoes to the brake rotor.

15. Check and adjust brake fluid level as necessary.

16. Road test the vehicle and make several stops to wear off any foreign material on the brakes and to seat the brake shoes.

_________________________________________________

When you are checking your work, make sure the inner brake pad is correctly inserted into the caliper piston and the anti rattle spring in the front is not loose and touching the rotor. Also, make sure the backing plate behind the brake rotor isn't bent or rusted and rubbing the brake rotor causing the noise.

Let me know what you find or if you have questions.

Take care,

Joe

Images (Click to make bigger)

Tuesday, April 28th, 2020 AT 7:00 PM