P0013- B Camshaft Pos Actuator Circ

It sounds like either the cam shaft position sensor is going bad or there is a wiring problem. Check to make sure the wires are clean and tight and not corroded.

ALLDATA Diagnostic Bulletin

RELATED VEHICLES: 2009 Cobalt, HHR, Pontiac G5 2.2L

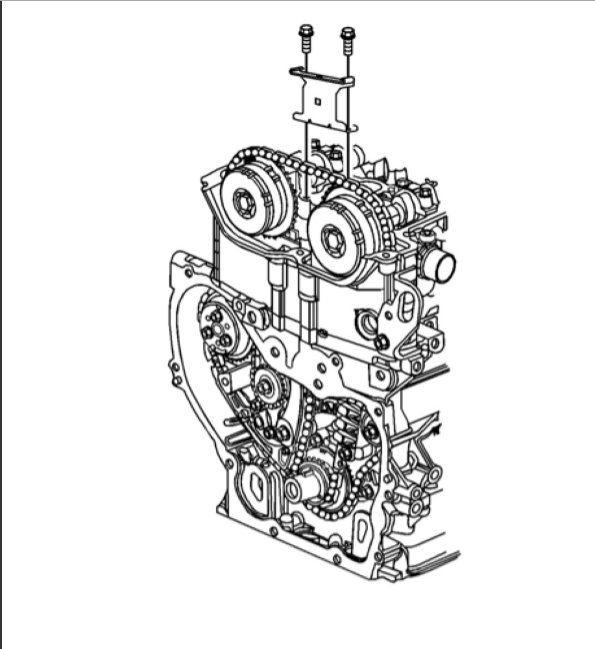

SUMMARY: P0010 - Intake Camshaft Position (CMP) Actuator Solenoid Control Circuit Fault; The camshaft position (CMP) actuator is attached to each camshaft and is hydraulically operated in order to change the angle of the camshaft relative to crankshaft position (CKP). The CMP actuator solenoid is controlled by the control module. The control module sends a pulse width modulated 12-volt signal to a CMP actuator solenoid. The solenoid controls the amount of engine oil flow to a CMP actuator. The CMP actuator can change the camshaft angle a maximum of 25 degrees. The control module increases the pulse width to accomplish the desired camshaft operation.

PROBABLE CAUSES:

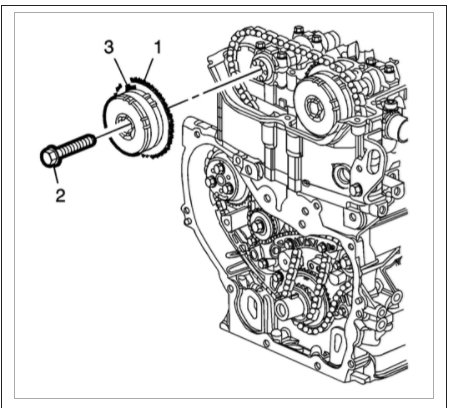

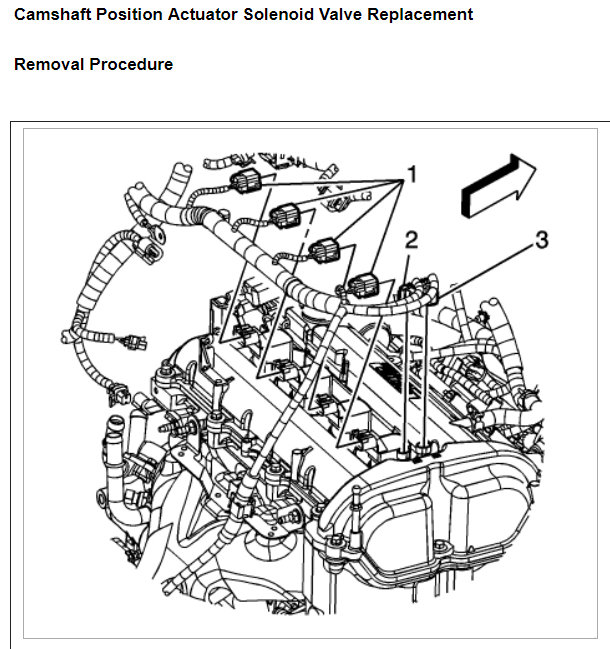

Intake Camshaft Position (CMP) Actuator Solenoid

Engine Oil Condition or Level

Engine Control Module (ECM)

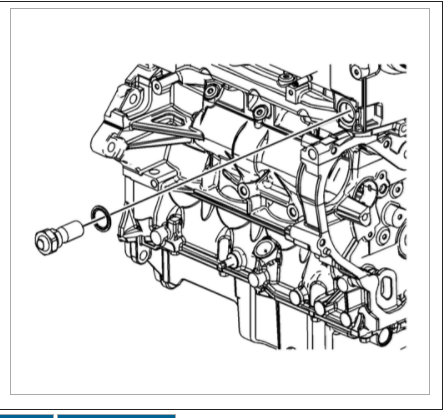

Excessive Timing Chain Play

DIAGNOSIS:

HINT: Measure the resistance of each CMP actuator solenoid valve assembly. Resistance should be between 8-12 ohms, if it is not within specification, replace the defective solenoid valve. Otherwise continue with the following troubleshooting.

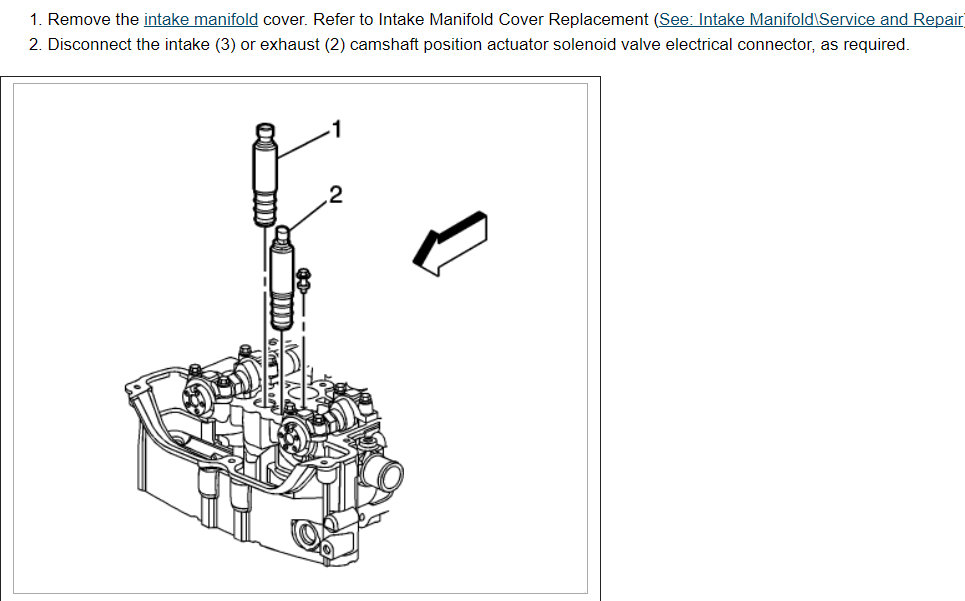

1. Ignition OFF, disconnect the CMP actuator solenoid harness connector at the CMP actuator solenoid.

2. Test for less than 5 ohms between the low reference circuit terminal B and ground.

If greater than the specified range, test the low reference circuit for an open/high resistance.

3. Verify that a test lamp does not illuminate between the low reference circuit terminal B and the control circuit terminal A.

If the test lamp illuminates, test the control circuit for short to voltage. If the circuit tests normal, replace the ECM.

4. Remove the test lamp.

5. Command the CMP Actuator Sol. ON with a capable scan tool. Verify the scan tool CMP actuator solenoid status is OK.

If not the specified value, test the control circuit for a short to ground. If the circuit tests normal, replace the ECM.

6. Install a 3A fused jumper wire between the control circuit terminal A and the low reference circuit terminal B. Command the CMP Actuator Sol. ON with a scan tool. Verify the scan tool CMP actuator solenoid status is Fault.

If not the specified value, test the control circuit for an open/high resistance. If the circuit tests normal, replace the ECM.

7. Determine that the vehicle has the correct engine oil.

If the engine oil life system monitor displays the Change Oil Soon message, the engine oil is more than one year old, contains additives, or is not the correct viscosity, change the oil.

8. Test the engine oil pressure.

If the oil pressure is low, correct the low pressure first.

9. Inspect each CMP actuator solenoid valve assembly for the following:

Torn screens

Debris on the screens

Debris clogging the oil ports

Missing screens

Oil seepage at the solenoid connector pins

10. Inspect for the following conditions:

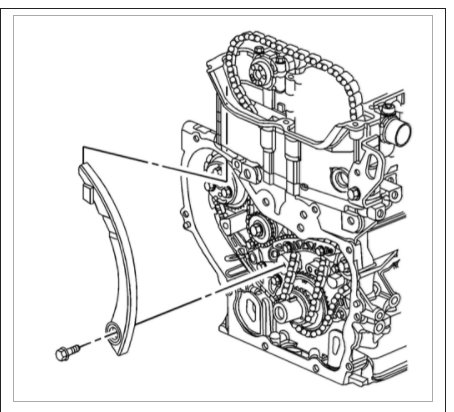

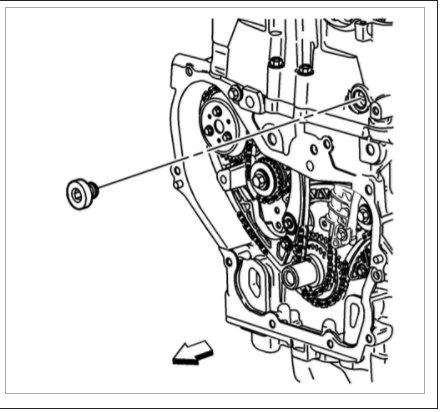

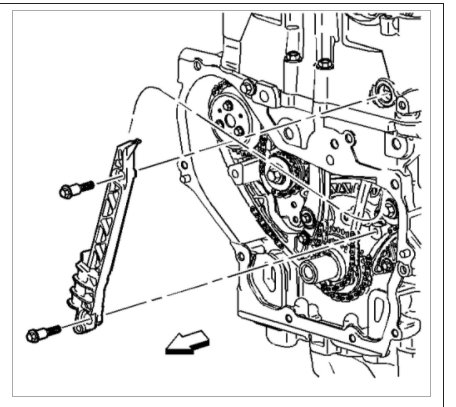

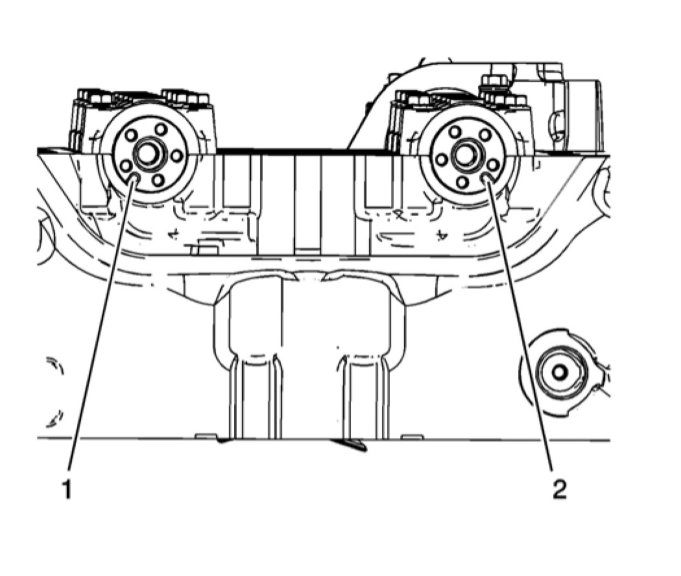

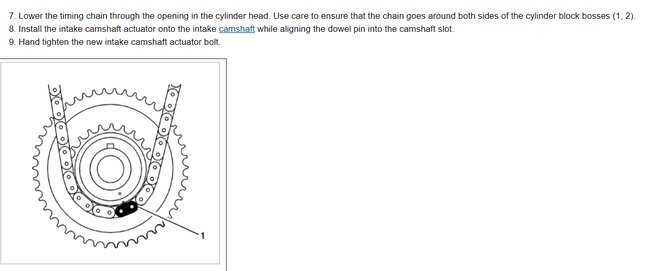

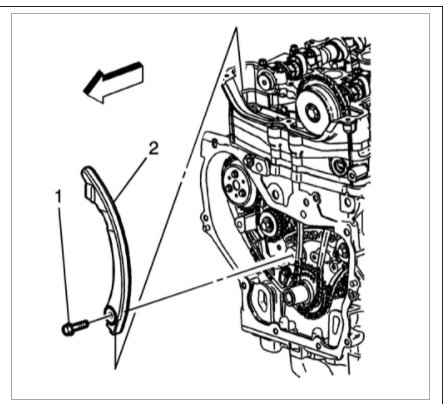

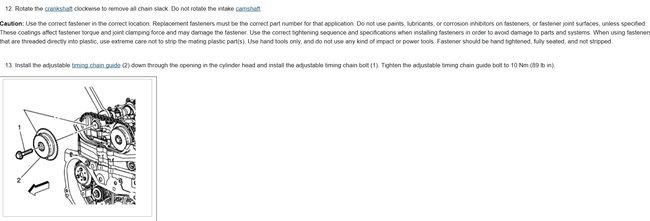

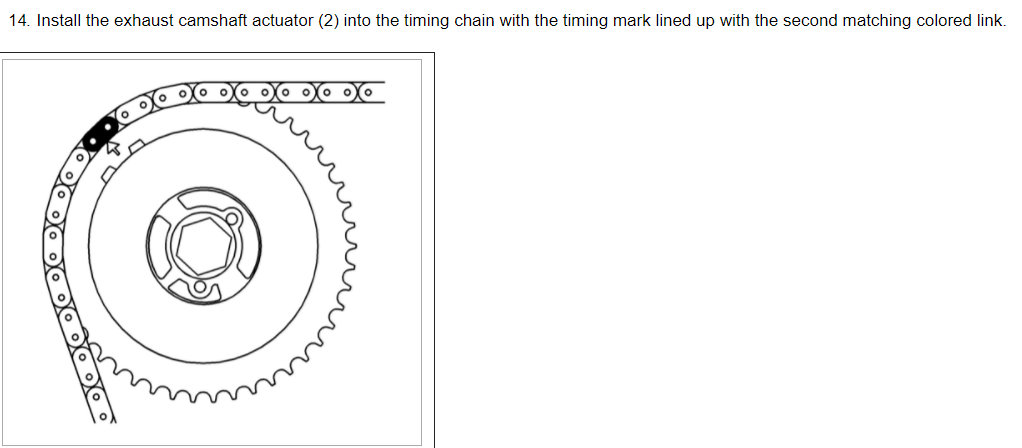

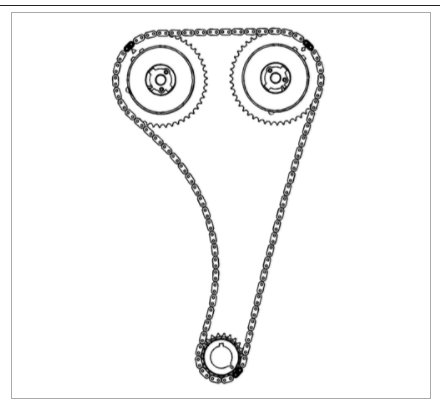

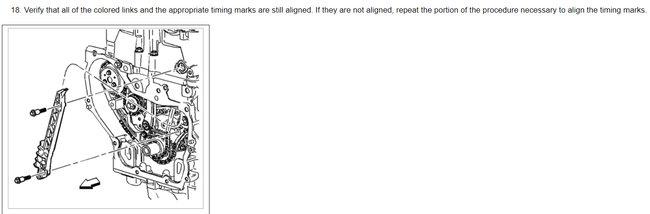

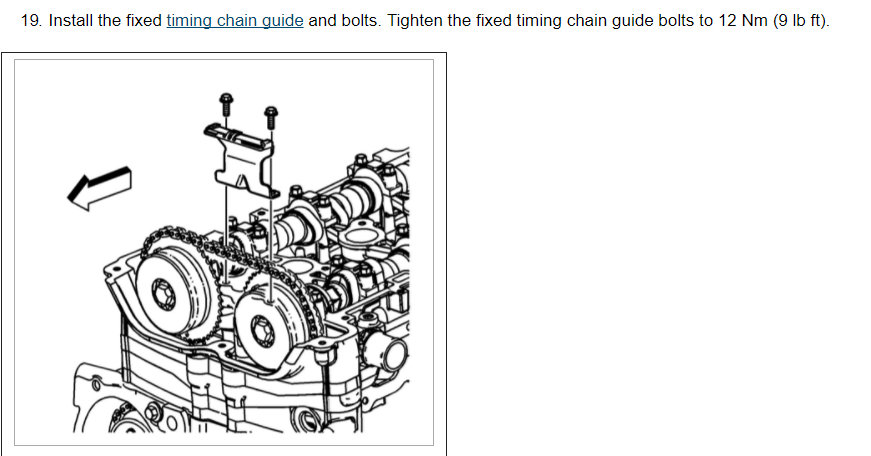

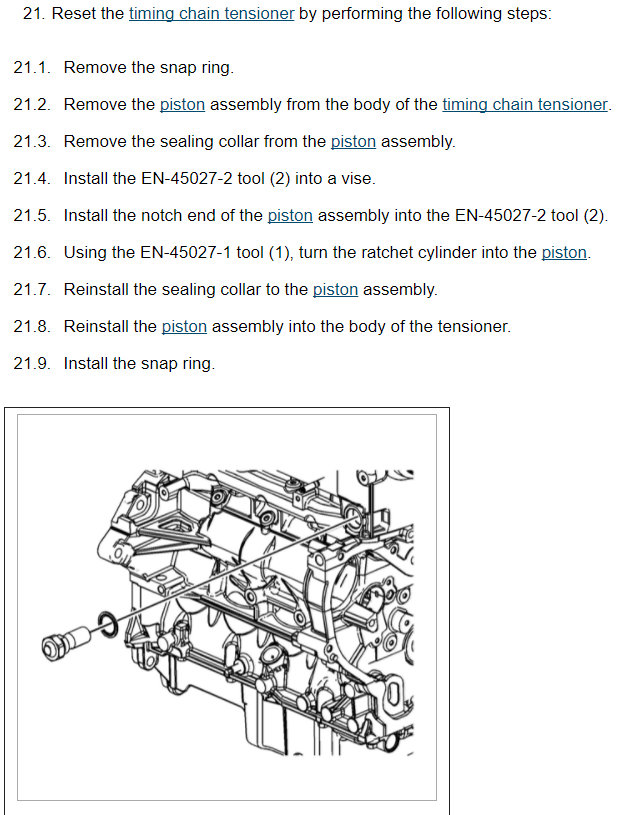

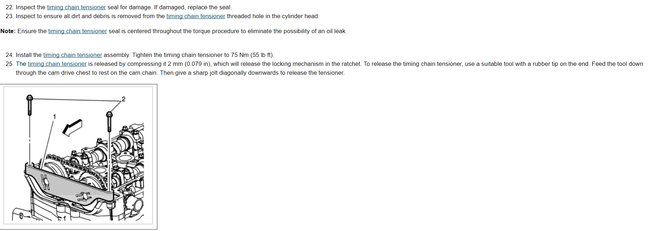

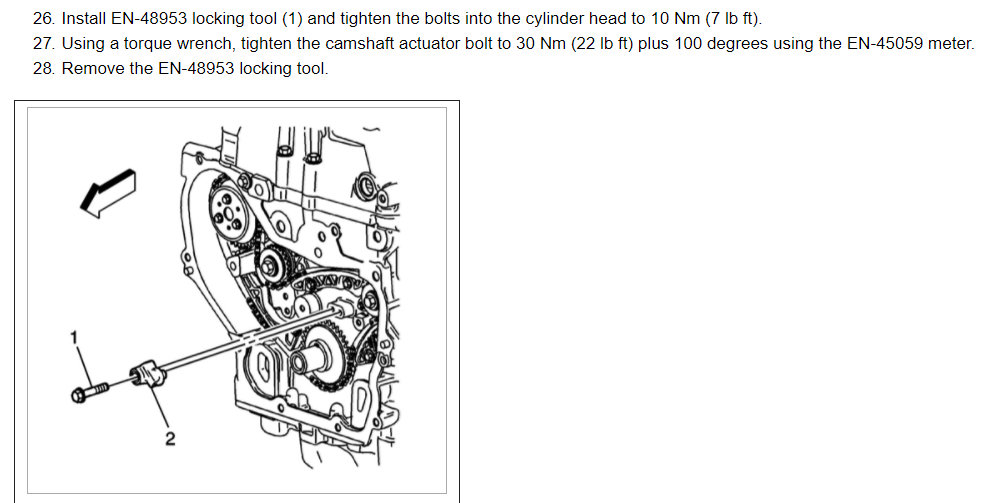

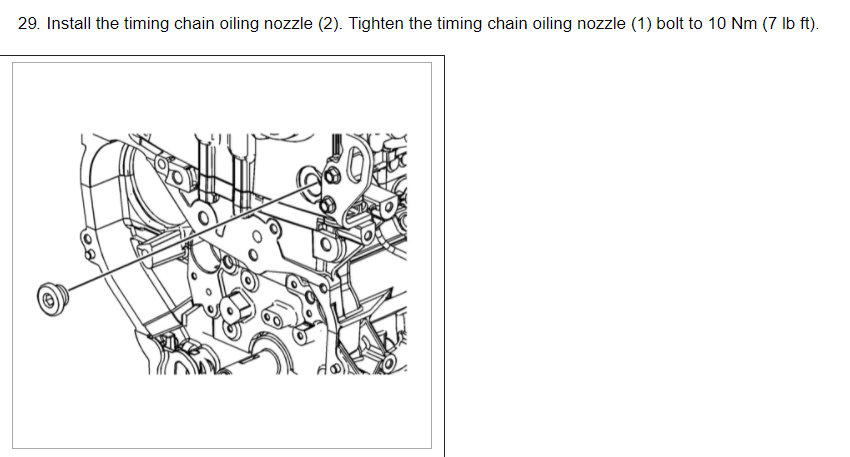

Excessive timing chain play

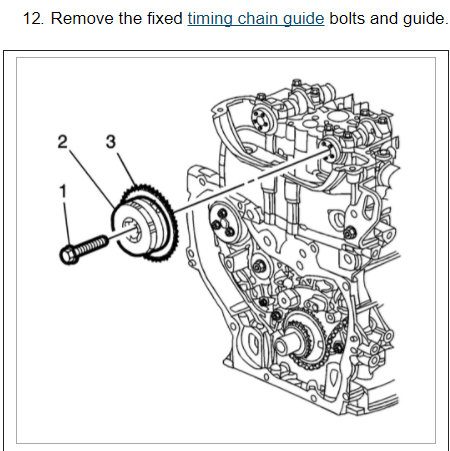

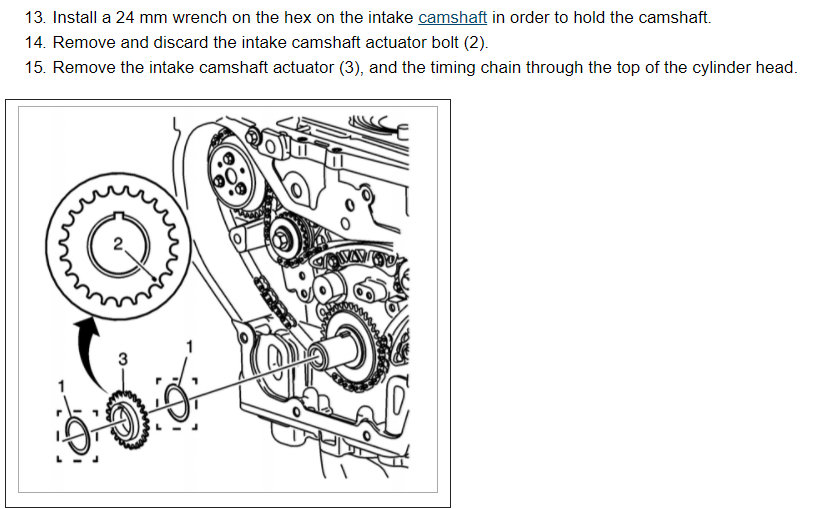

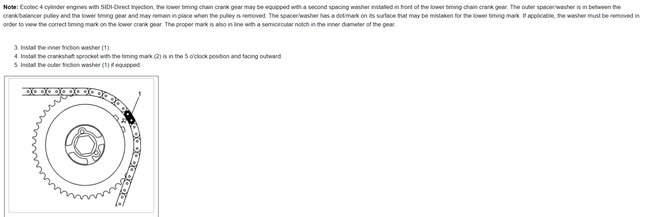

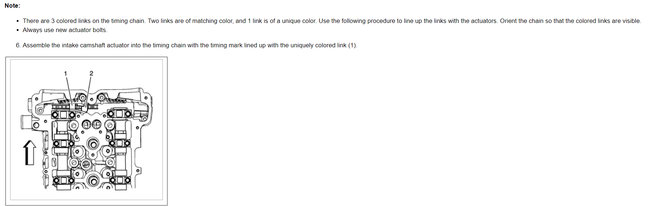

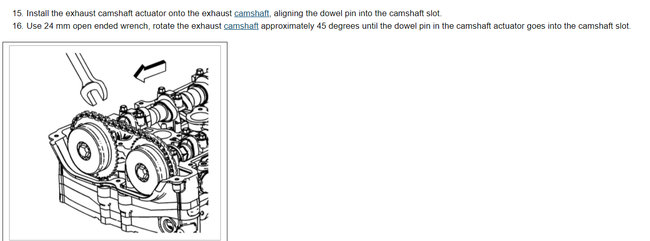

Proper installation of the CMP actuator assembly

If all tests are normal, replace the CMP actuator solenoid.

SPONSORED LINKS

Saturday, July 13th, 2013 AT 8:08 PM