This is a very common problem that only applies to GM trucks. It's caused by rust build-up under one of the front ABS wheel speed sensors.

To generate a signal voltage, you need three things; a coil of wire, a magnet, and most importantly, movement between them. In this case, the wheel speed sensor is a coil of wire wrapped around a magnet, then the movement is actually the magnet's magnetic field being disturbed by the passing teeth on the tone ring. GM puts that tone ring inside their wheel bearing assemblies, but the sensor sits outside where water can get under its mounting pad, causing rust to form and build up. As it does, it pushes the sensor away from the tone ring.

These sensors develop real wimpy signals to start with, then they become even weaker when the air gap increases. Next, since movement is a factor in signal strength, the signals become even weaker as wheel speed slows down. By the time you get down to around 10 mph, the signal becomes too weak to be analyzed by the computer. It thinks that wheel has locked up, so it activates the various valves to try to get that wheel rotating again. That's called "false activation". It's the operation of those valves you're feeling.

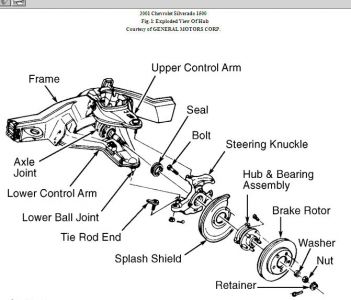

The fix is usually to remove the sensor to clean off any rust under it. Many people replace the entire wheel bearing assembly, but most of the time that is not necessary. The red arrow is pointing to the area where the rust forms.

Image (Click to make bigger)

Tuesday, February 23rd, 2021 AT 9:07 AM

(Merged)