What you're describing is typical of a bad diode. Technically speaking, you have an AC generator but when you call it an alternator, everyone will know what you're talking about. Chrysler was the first to use an AC generator in 1960 and they copyrighted the term "alternator". As a former instructor it was important to always use correct terminology to avoid confusion, and I'm still used to doing that.

It's also important to understand that it will not produce more current than what is needed by the electrical system. It only has the CAPABILITY of producing more when it is needed. All generators need movement, (rotation), as one of the three things needed to cause current to flow, so they are always less efficient at lower engine speeds. It still should be able to keep up for most conditions when at idle. For the output voltage and / or current to drop means it can't keep up at that engine speed. That is typical when one diode is defective. AC generators put out three phase output which is very efficient, but with one bad diode, one phase is lost. The result is it will only be capable of developing exactly one third of its normal rating, which in your case is around 65 amps.

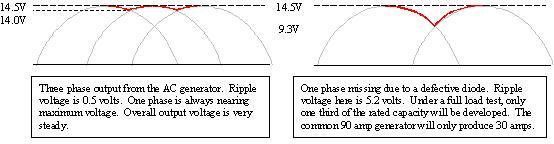

65 amps is plenty to run the electrical system under normal conditions but "ripple" also comes into play. Here's two sad drawings from my web site that shows ripple. The voltage regulator monitors that voltage and tries to adjust the generator's output CURRENT to maintain proper system and battery voltage. Think of a large water pump having to pump the proper volume of water, (current), to fill a municipal water tower at the same rate people are using water, to maintain the proper weight of water in the tower which produces pressure, (voltage).

When the voltage regulator sees the drop due to the missing phase, it bumps up the strength of the generator to try to get the voltage back up. Later it sees the output from the working phases is too high and tries to cut back. The result is flickering lights due to pulsing voltage levels.

I would start with a load-test on your system to verify the generator can produce near its rated output. If it can, for the dropping at idle, look at the size of the pulley. It takes a lot of horsepower to run a regular generator, and to run a really large one often they will put on larger pulleys so they drag the engine down less. That will show up at idle as the same drop in voltage as a defective diode would cause.

Because of the lower efficiency at low speeds, one part of a proper load-test is to raise engine speed to around 2000 rpm. No generator or alternator will produce its maximum rated output at idle.

Image (Click to make bigger)

Tuesday, February 12th, 2013 AT 5:28 AM