Hi Kenny K. I see this an old post. My comments are meant more for others who might be researching this topic. Please forgive me for butting in.

One real common thing to look for is if the battery was recently disconnected or run dead. When that happens, a lot of stuff has to be relearned. Most of that, like fuel trim numbers and sensor personalities takes place right away without anyone noticing as soon as you start driving. The one big exception that to my knowledge only applies to Chrysler products is "minimum throttle". Until that is relearned, idle speed will be too low. The engine may not start during cranking unless the accelerator pedal is held down 1/4". The engine will tend to stall at stop signs, and it won't give the normal "idle flare-up" to 1500 rpm at start-up. The big clue is stalling never occurs during normal driving until you take your foot off the pedal to coast to a stop. This is the only parameter that requires specific driver actions to do the relearn.

To relearn minimum throttle, the computer needs to see a stable signal voltage from the throttle position sensor, and it wants to know your foot is off the accelerator pedal. It knows your foot is off the pedal by seeing high intake manifold vacuum. High vacuum can only occur with a closed throttle. That can happen in the shop by snapping the throttle and releasing it quickly, but then you intentionally may not release it all the way to curb idle. To address that, it needs to see high vacuum for at least seven seconds. The only way to achieve that is to be on a test-drive, and coast down from highway speed with the throttle closed. If your foot is on the pedal yet, road vibration will cause the TPS voltage to bounce around, even by as little as a few hundredths of a volt. That is enough to abort the relearn. Same thing if your foot is on the brake pedal. That cancels any relearn from taking place.

The short answer for this relearn is to "drive at highway speed with the engine warmed up, then coast for at least seven seconds with your feet off the pedals".

At the end of that seven seconds, if the TPS signal voltage held steady, that voltage gets put in memory. From then on, any time the computer sees that voltage, it knows it has to be in control of idle speed. Chrysler and GM use the same idle speed motor, but they use different terminology related to their operation. This is a "stepper" motor that has an armature that is slowly rotated to various positions when the computer pulses its four coils with varying voltages and polarities. The armature can rotate roughly ten turns in total stopping at one of 256 positions called "steps". As the threaded shaft rotates, it extends or retracts a pintle valve. That valve opens an air passage that bypasses the throttle blade. As it opens more, the length of time the fuel injectors are pulsed open increases. With more air and more fuel, idle speed increases.

The reason for bringing up the "steps" is it is part of the diagnostic procedure for a low idle speed complaint. First, if the relearn procedure doesn't solve the issue, do it again while holding the brake pedal up with your foot. If the brake light switch is out-of-adjustment, bumps in the road can cause it to cancel the relearn. Associated with that is often the cruise control kicks out intermittently. The cruise cut-off uses a different section of the brake light switch. It has its own dedicated switch within the assembly. The minimum throttle relearn function wants to see no 12 volts on the part of the switch that feeds the brake lights.

The idle speed steps can be read on any scanner under the "live data" screen. For a properly running engine, step 32 is typical. To put this in perspective, if you disable one cylinder on an 8-cylinder engine, you can expect to find it has been bumped up to around step 50. In a Jeep training class, the instructor wanted to show how much control the computer has over idle speed. One by one, he unplugged six injectors on a running V-8 engine. Obviously, it ran very rough, but it did maintain the desired idle speed, and it was just over step 200.

Reading the step number can help with a number of things. First, if it's moving around a lot, look for things that would cause surging or erratic idle speed on carbureted engines. Low fuel pressure, restricted air filter, dry-rotted and cracked vacuum hoses, and worn spark plugs are good suspects. With those problems on fuel-injected engines, the computer has to really work that idle speed motor to try to hold speed steady. If you see it at around step 50, suspect the computer is trying to overcome the idle speed drop caused by a single-cylinder misfire. "96 and newer models will likely also have a diagnostic fault code indicating the responsible cylinder.

Here's the biggee. If you find it at step "0", regardless of the cause, minimum throttle hasn't been relearned yet. The scanner won't list a reason, but it may show data that lets you figure out the reason. For example, under the "Inputs / Outputs" menu or the "Switch State" menu, check if the brake light switch is listed as "Applied" or "Released". Also watch the TPS signal voltage for signs of bouncing around while coasting during the test-drive. That can be caused by a tight throttle cable or weak or dirty terminals in the TPS connector.

No two sensors are ever exactly alike. If the TPS is replaced, you have a 50 percent chance the new one will have a lower voltage reading at idle than the old sensor had, and a 50 percent chance it will be higher. Typically, you can expect it be around.70 volts, but for training purposes, the standard values we use in the discussion is the acceptable range from idle to wide-open-throttle is 0.5 to 4.5 volts. The point is, if the idle voltage from the new sensor is higher than that of the old sensor, the computer is going to think you're holding the accelerator pedal down, so it will leave idle speed up to you. This could lead to stalling or a failure to start. This is where the relearn procedure has to be done. For most competent do-it-yourselfers, they usually meet those requirements unknowingly while driving, then they don't know why the low idle problem solved itself.

On the other hand, if the new TPS has a lower signal voltage at idle than the old sensor had, the computer will instantly see that a "new low" has been reached, and it will immediately put that new value in memory. No relearn test-drive will be needed.

Reading the step numbers will also tell you what types of things to look for when idle speed is wrong. If idle speed is too high, by far the most common cause is a vacuum leak. The computer will try to correct that by placing the idle speed motor at a lower step. You might see it as low as perhaps step 10 to step 15. It's lower than the normal step 30 to step 34, but it will never go as low as step 0. Remember, step 0 means minimum throttle hasn't been learned. At a lower step number, the computer is trying to lower idle speed, but without success.

Next, if idle speed is too high, as before, but you find the idle speed at, ... Let's say, step 40, the computer is requesting that higher idle speed in response to something. Most often this is due to the reading from a temperature sensor. Also look for a thermostat that's stuck open resulting in the coolant not reaching normal operating temperature. In winter, the AC compressor runs any time the heater is in "defrost" mode to remove moisture from the air so it won't condense on the cold windshield. The computer is going to bump up the idle step number to overcome the additional load of the compressor on the engine. If the compressor is unplugged, as some owners do in winter, or it isn't cycling on for some other reason, the additional load isn't there, so idle speed will go up a little.

When idle speed is too low, but you find a high number for the idle speed step, the computer sees that low speed, and is trying to correct it but without success. This is where I'd first suspect low fuel pressure, particularly on GM engines. Chrysler engines of this era were extremely forgiving of low fuel pressure, and their pumps rarely caused that issue. In the late '80s through the mid '90s, it was much more common to find the air passage around the throttle blade was totally plugged with carbon from fuel vaporizing in the intake manifold after the engine was stopped. No matter how many steps higher the computer placed the idle speed motor, the valve's opening being blocked with carbon prevented the extra air from getting in. Idle speed couldn't increase enough, but you'd see the high step number. For Chrysler products, this mostly affected their Mitsubishi-built 3.0L engines. With better fuel additives today, I haven't seen those blocked passages for over 25 years.

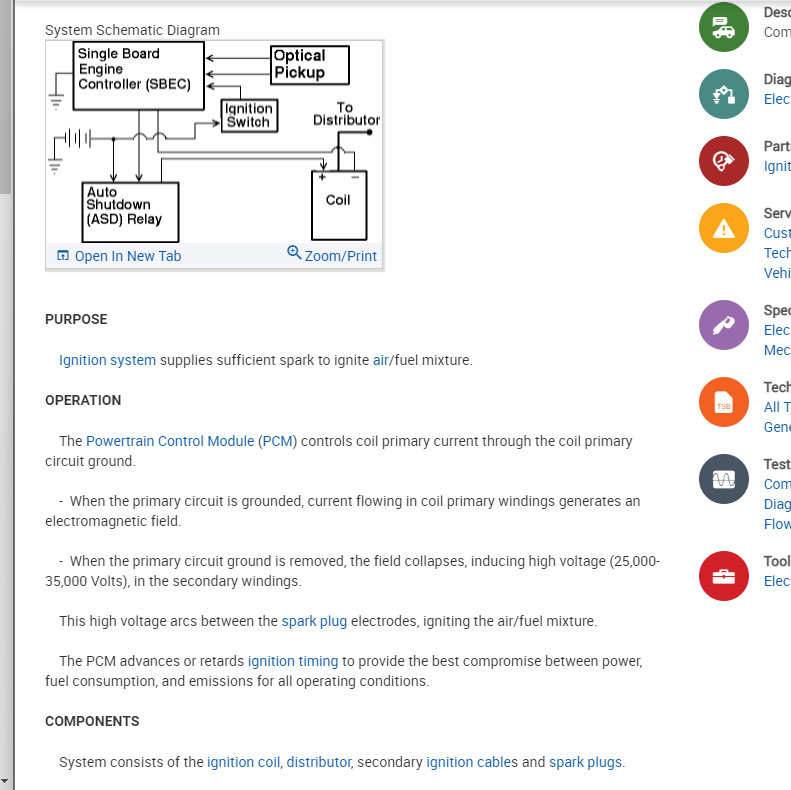

You mentioned the automatic shutdown, (ASD) relay too. The computer needs to see signal pulses from the crankshaft position sensor and the camshaft position sensor during engine rotation, (cranking or running). When it does, it turns on the ASD relay which sends current to the ignition coil(s), injectors, and fuel pump or pump relay. If stalling occurs while driving and while the accelerator pedal is being held down, that has a different cause than loss of minimum throttle. A scanner with the "Record" feature can help with the diagnosis. About five seconds worth of data gets recorded when the event occurs. When it is played back slowly, later, the recording can show if the cam or crank sensor signal dropped out first, in which case you'd lose both ignition coil and injector pulses at exactly the same time, and the ASD relay would get turned off roughly one or two seconds later as a result, or whether spark or fuel pressure was lost first, then the engine stalled a few seconds after coasting to a stop, and then as a result, the cam and crank sensor signal pulses stopped showing up. The order in which things are lost can usually only be learned by using a scanner. Knowing which occurred first will get you to the right circuit to diagnose.

Monday, January 24th, 2022 AT 2:11 PM