1. Relieve� fuel� pressure.� See FUEL� SYSTEM� PRESSURE� RELIEF.� Connect� Fuel� Pressure� Gauge� (J 34730 1)� to� fuel� pressure� connector.� Turn� ignition� on.� With� ignition� on� and� engine� off, � pressure� should� be

54 64� psi� (3.8 4.5� kg/cm2� )� and� should� hold� steady.

2. If� pressure� is� within� specification� and� holds, � go� to� next� step.� If� pressure� is� within� specification� but� does� not� hold, � go� to� step� 4).� If� fuel� pressure� is� not� present, � go� to� step� 7).� If� pressure� is� greater� than� specification,

go� to� step� 9).� If� pressure� is� less� than� specification, � go� to� step� 5).

3. Start� engine.� With� engine� at� operating� temperature, � open� throttle� quickly� and� note� fuel� pressure.� If� fuel� pressure� is� not� close� to64� psi� (4.5� kg/cm2� ), � replace� CPI� assembly.� If� fuel� pressure� is� close� to� 64� psi� (4.5

kg/cm2� ), � problem� does� not� exist.

4. Check� for� leaking� injectors� or� fittings� by� pinching� off� fuel� return� line.� If� pressure� does� not� hold, � replace� CPI� assembly.� If� pressure� holds, � check� for� faulty� in tank� fuel� pump� or� pump� connections.

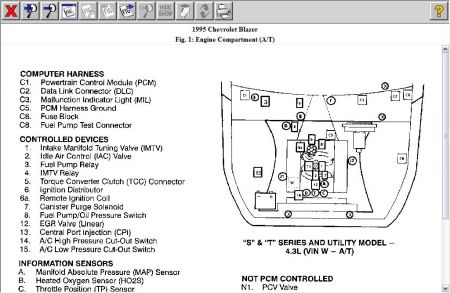

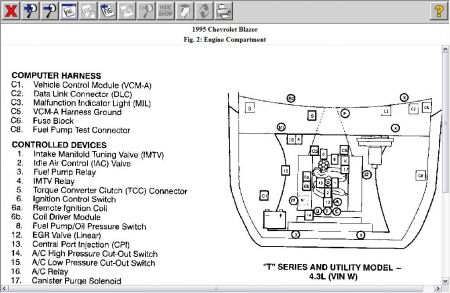

5. Check� for� restricted� delivery� line� or� fuel� filter.� Repair� as� necessary.� If� no� restriction� is� evident, � apply� battery� voltage� to� fuel� pump� test� connector� using� a� 10 amp� fused� jumper� wire.� For� location� of� fuel� pump� test

connector, � see� COMPONENT� LOCATIONS� in SYSTEM/COMPONENT� TESTS � 4.3L� article.

6. Gradually� pinch� off� flexible� fuel� return� line� between� CPI� assembly� and� fuel� tank.� If� fuel� pressure� increases� to� within� specification, � pressure� regulator� is� faulty.� Replace� CPI� assembly.� If� fuel� pressure� does� not

increase� with� line� pinched, � check� for� faulty� in tank� fuel� pump, � loose� pump� connections� or� partially� blocked� fuel� strainer.

7. Use� a� 10 amp� fused� jumper� wire� to� apply� battery� voltage� to� fuel� pump� test� connector.� For� location� of� fuel� pump� test� connector, � see� COMPONENT� LOCATIONS� in SYSTEM/COMPONENT� TESTS � 4.3L

article.� Observe� fuel� pressure� reading.� If� fuel� pressure� is� still� not� present, � check� wiring� between� test� connector� and� fuel� pump.� If� wiring� is� okay, � replace� fuel� pump.

8. If� fuel� pressure� is� present� with� voltage� applied� to� test� connector, � test� fuel� pump� relay� and� voltage� supply� to� relay.� See SYSTEM/COMPONENT� TESTS � 4.3L� article.

9. Relieve� fuel� pressure.� Disconnect� fuel� return� line.� Attach� a� 5/16"� flexible� fuel� line� to� CPI� side� of� fuel� line.� Route� hose� into� appropriate� container.� Turn� ignition� on, � and� note� fuel� pressure.� If� fuel� pressure� is� within

specification, � locate� and� repair� restriction� in� fuel� return� line.� If� fuel� pressure� is� still� greater� than� specification, � replace� CPI� assembly.

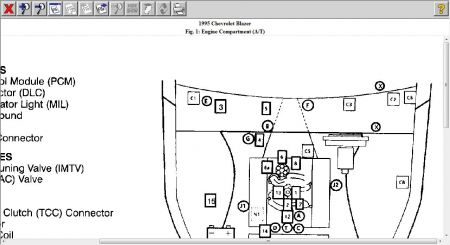

Also a new regulator doesn't mean it's good either. Also check battery and clean terminal ends. Load test battery. Check out the diagrams (Below). Please let us know what happens.

Images (Click to make bigger)

Saturday, January 30th, 2021 AT 8:35 AM

(Merged)