Forget the idle air control valve, (IAC), (automatic idle speed motor, (AIS)), or whatever name is used by other manufacturers. That unit simply controls the volume of air allowed to bypass the throttle blade. At the same time the Engine Computer adjusts the length of time the injectors are pulsed open to control the amount of fuel. The only purpose is to adjust idle speed, not idle or running quality.

The EGR valve doesn't open at idle or low engine speeds or when the engine is cold. It should only open when its actions won't be noticed, typically at highway speeds. It is possible for it to cause rough idle when a chip of carbon breaks off and prevents the valve from closing completely. A common way to identify that is to loosen or remove the valve assembly, then reinstall it with a thin piece of sheet metal or shim stock to block the port. If the rough idle can still be made to occur, it's not due to that valve.

Oxygen sensors also have nothing to do with rough idle. Based on its readings, the computer adjusts the amount of fuel being sprayed in to keep the air / fuel mixture as close to perfect as possible. Those readings can only result in a change of about plus or minus ten percent from the default, or normal values. Incorrect operation results in increased emissions and possibly a little black smoke from the tail pipe.

The only common, but still rare problem a throttle body can cause as far as engine performance is a vacuum leak around the throttle blade shaft. That could result in erratic idle speed, just like any other vacuum leak would cause. Other than that, there are no moving parts or anything to wear like there were in carburetors. Some engines were prone to surging idle speed when carbon deposits built up on the back side of the throttle blade, but we don't see much of that anymore, in part due to better fuel additives.

A couple of thoughts come to mind for the symptom you described. While this doesn't match exactly, consider checking the ignition timing with a timing light when the engine is at a steady, low idle speed. The exact value isn't the issue. Watch the timing mark to see if it is bouncing around, especially a good ten degrees or more. If you see that, check for worn bushings in the distributor that allow the shaft to wobble around. When the magnetic pickup coil is in there, the timing pulses will vary and bounce around. For most of those pickup designs, the air gap is rather critical. A wobbling shaft can let the toothed reluctor wheel move away from the sensor's magnet. A timing pulse can fail to be big enough to be read by the computer. Lacking that pulse, the ignition coil won't fire for that cylinder. A trick to help identify that is to trigger the timing light from all of the spark plug wires, one at a time. If you only use cylinder number one, that one might never drop out, but say you use cylinder number three's spark plug wire, that one might show intermittent loss of ignition pulses when the rough running occurs.

While that last problem can cause intermittent loss of spark to individual cylinders periodically, you can also have loose or sloppy timing chains on many engines. That also allows erratic idle speed due to spark timing changes, by not so much a rough idle. Your engine uses a timing belt, so that is not likely to cause this problem.

If this were to occur right after very high-speed operation, such as with racing engines, suspect hydraulic lifters that have pumped up due to "valve float". That can result in a couple of valves being held open until those lifters bleed down. That can take as much as 15 to 20 seconds. That lifter pump up doesn't occur under normal engine speeds unless a valve spring is broken or very weak.

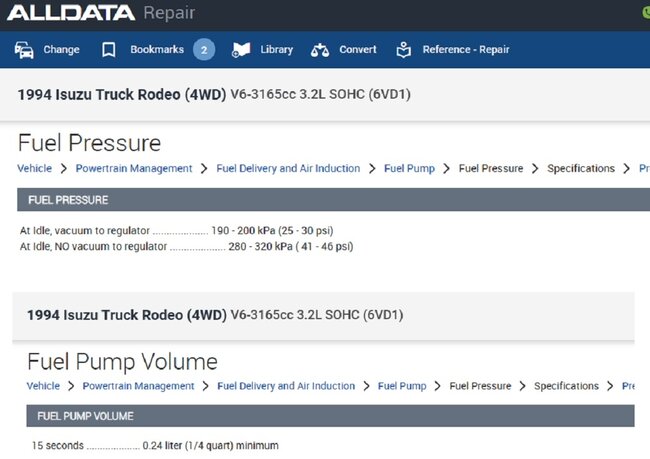

Probably the better place to start looking is at fuel pressure. For most engines with throttle body fuel injection, a fuel pressure regulator is built in that adjusts pressure through a vacuum hose connected to intake manifold vacuum. Two forces act on a molecule of fuel when it leaves the tip of the injector, that's fuel pressure and intake manifold vacuum. During periods of high load or acceleration, vacuum goes down, so fuel pressure is increased to offset that. Where problems occur more often is during coasting or when engine speed or load goes down. During coasting, vacuum is high. On its own, that would tug the fuel out of the injectors too aggressively, resulting in a rich coasting condition with greatly increased emissions. To prevent that, the vacuum hose to the fuel pressure regulator relaxes its internal spring, lowering fuel pressure. The net difference between the two forces, vacuum and fuel pressure, remains steady. The problem comes from that relaxed pressure regulator. The fuel pump moves a really large volume of fuel, say a gallon per minute, to the engine. Well over 99 percent of that fuel flows through the pressure regulator, then right back into the tank through the fuel return line. When the high vacuum signal tells the pressure regulator to relax, it is much easier for the gas to get through it, so the fuel volume being moved by the pump goes way up. (Less fuel going into the engine, but a lot more going through the pump), and more fuel volume that needs to get through the pickup sock, or screen, under the fuel pump housing. When that screen becomes blocked, or collapses after a few minutes of driving, insufficient volume can get through. That results in drastically reduced fuel pressure, often to the point not enough fuel gets into a cylinder for it to fire properly. Most often this causes stalling when coasting down from highway speed, and the engine runs best during acceleration and high=speed driving, but we still look at low fuel pressure for rough running complaints. Fuel filters should be at the bottom of the list of suspects when the symptoms only occur when the engine using very little fuel.

I'm going to share one more thought although I don't think this is the issue here. Based on multiple repair attempts so far, there's a good chance the owner has disconnected the battery a few times. Once reconnected and the engine is started, all sensor personalities are relearned right away, but often idle speed needs a specific set of condition for the computer to relearn when it must be in control of idle speed. This has been an extremely common concern among Chrysler owners who usually become confused when the low idle speed problem seems to fix itself. In reality, a very specific set of conditions must be met for "minimum throttle" to be relearned, but that requires driving the vehicle. For most other car brands, we don't usually hear about these problems as they have different strategies for doing these relearns. My reason for bringing this up is this may be one of those cases where at some point, idle speed goes way too low, then it takes some time for the computer to react and recover that minimum speed. You may not be feeling roughness due to cylinders cutting out. It may just be from the engine idling to slowly. You didn't say what, "a but" is as far as how much time the rough idle occurs, but the way I'd start looking at this is to be ready at the throttle body, and as soon as the roughness occurs, raise idle speed manually and see if that roughness clears up. If it still doesn't feel right, start with the fuel pressure test. If the EGR valve uses vacuum or electrical controls, unplug everything going to that valve so it won't open. Now if the roughness doesn't occur, look for carbon blocking the sealing of the valve.

Related to EGR problems that used to be common on Ford engines was a tube plugged with carbon. Rather than sending EGR gas into the intake manifold at one point, Ford sent it down a long tub with branches that fed each cylinder. As those individual branches became plugged, those cylinders ran especially well because all they got was fresh, clean fuel and air. The problem was the system was based on volume, so as more and more tubes became plugged, more of that volume went to the cylinders with tubes that weren't plugged yet. Eventually the last one or two cylinders were getting all of the EGT gas which was so high, it prevented normal combustion. This still should not be occurring at low engine speeds. It caused misfires at higher speeds when the EGR valve was expected to open.

See if those ideas get you anywhere.

Sunday, April 21st, 2024 AT 11:49 PM